The Bottle Blowing Process: A Key Element in the Beverage Packaging Industry

The art of bottle blowing is a critical operation in the beverage and food packaging industry, where precision, efficiency, and cleanliness are of utmost importance. Whether it's a mineral water bottle, a multi-layered juice container, or a sturdy beer can, the process of creating these bottles is a blend of craftsmanship and advanced technology. Let's delve into the detailed steps involved in the bottle blowing process, focusing on the pivotal roles of the PET bottle blowing machine.

The Versatility of Bottle Blowing Machines

Bottle blowing machines are designed to accommodate a wide range of products, each presenting its unique set of challenges. Here's how they cater to different container requirements:

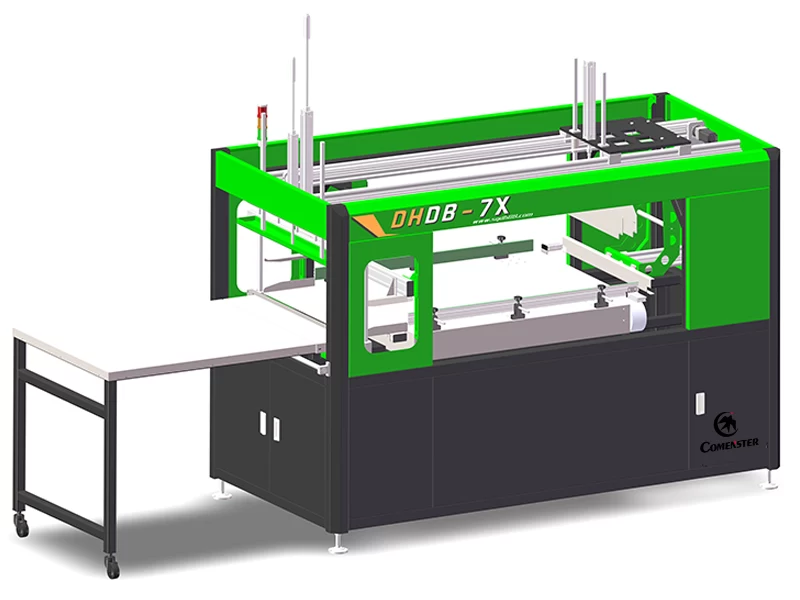

PET Bottle Blow Molding Machine: These machines are specialized for the production of PET bottles, ensuring that the bottles are lightweight, durable, and suitable for various beverages, including water, soda, and juice.

The Bottle Blowing Process The process of creating bottles for beverages involves several stages, each meticulously crafted to ensure quality and efficiency:

Preform Heating: The plastic preform is heated to its optimal temperature, ensuring it is malleable and ready for the blowing process.

Blow Molding: The heated preform is placed in a mold and air pressure is applied to shape it into the desired bottle form. The PET bottle blowing machine, for example, uses precise control of air pressure and temperature to create a uniform bottle shape.

Cooling: The newly formed bottle is cooled to solidify its shape and ensure it retains its form once removed from the mold.

Quality Check: After the bottles are formed, they undergo a series of quality checks to ensure that they meet the required specifications for size, shape, and material integrity.

Choosing the Right Bottle Blowing Machine Manufacturers When selecting a bottle blowing machine, it's crucial to partner with reputable manufacturers who understand the specific needs of your product. Look for manufacturers that offer:

Customization: Machines that can be tailored to the specific requirements of your container design.

Reliability: A history of producing machines that are durable and efficient in operation.

After-sales Support: Comprehensive service and support to ensure uninterrupted production.

In conclusion, the bottle blowing process is a sophisticated interplay of technology and craftsmanship, designed to produce a flawless container every time. Whether it's a PET bottle blowing machine or any other specialized equipment, the right machine can make all the difference in the quality and durability of your bottles. By understanding the process and selecting the right bottle blowing machine manufacturers, you can ensure that your product is packaged in the best possible way, ready to reach the market in its finest form.