- Home

- Solution

- Products

- Services

- Blog

- About

- Contact

Bottled water is indispensable in people's lives, whether it is sports, home or office, all play a major role. So how much does it cost to invest in a bottled water production line? The next step is to introduce you to a 9000-12000 bottled water production line required equipment and cost investment in detail.

Comenster manufacturers provide the small plastic bottles of full automatic bottled water production line with high degree of automation, easy to operate.

Plastic bottle capacity applicable range: 200ml,550ml,1.5L,2L,2.5L

Filling liquid:Mineral water、Spring water、Sparkling water、Soda water、Coconut water、Hydrogen water

Water source can be groundwater or tap water to ensure that the quality of water to meet national standards for pure water. This system includes the original water tank, water treatment, sterilization equipment, pure water tank and so on. 9000-12000 bottled water production line is recommend ed to configure 8T-10T water treatment.

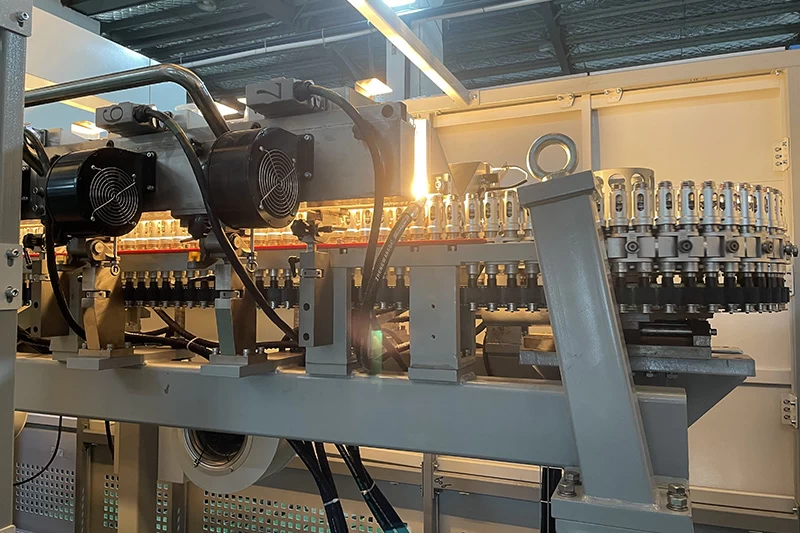

TAccording to the production line capacity 6000BPH, we recommend you to use high speed 4 cavity blow molding machine , automatically loading the preforms, save labor.

Fully Automatic High Speed 4 cavity Blow Molding Machine

Adopting full-automatic 3-1 bottled water filling machine, washing, filling and capping in one machine, which ensures the hygiene and quietness of the product and reduces the labor Applicable range: plastic bottles PET bottled water, pure water, alcoholic beverage machinery and other non-gas beverage machinery.

Recommended Model: 16-16-5 Automatic Filling Machine

Access to clean water is essential for maintaining human health and well-being. There are numerous sources of drinking water, which require different treatment processes. We provide a comprehensive range of solutions for various water sources, including water treatment systems, injection systems, blowing machines, filling machines, packaging machines, conveyor systems, electrical systems, cables and wires, and the relevant raw materials, such as preforms, caps, plastic particles, labels, shrink film, clean room building materials, and more. In addition, we provide a complete service from start to finish, including pre-sale planning drawings, post-sale installation, commissioning, and maintenance. The following is a list of the types of previous customers we've had the pleasure to work with:

1. If you'd like to make the same product, we can provide samples of our overall project plan for your reference.

2. If you'd like to make a different product, we're happy to work with you to create a new overall project plan.

Mineral water

Spring water

Sparkling water

Soda water

Coconut waterr

Hydrogen water

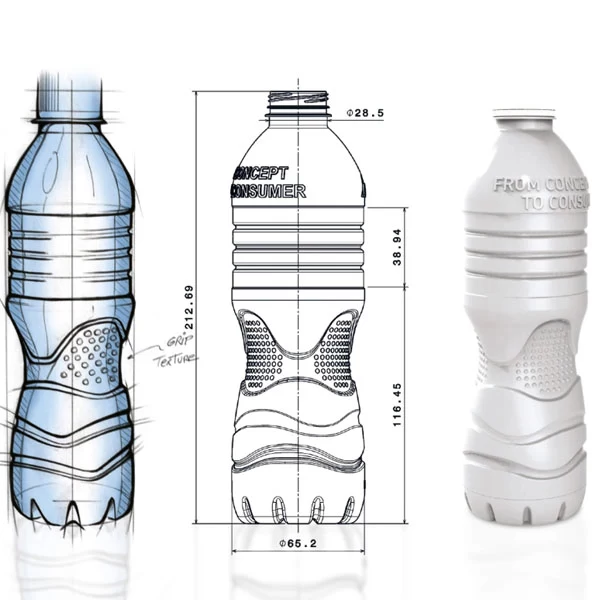

Bottle Type design:

Comenster professional technical team, according to your needs for free bottle design, for you to recommend the right bottle structure, to increase the competitiveness of your products in the market, and at the same time according to the market situation of your country for you to recommend the right bottle type.

According to the different needs of customers and bottle drawings, customize the filling and packaging equipment scheme.

As shown below:

We can supply bottle preform, caps, label rolls with very reasonable price.

Comenster offers the complete line solutions of water,beverage,milk,beer,edible oil and cosmetic manufacturers and so on: process technology,bottle blowing technology,filling technology and packaging technology and other marketing services.We promise you the most reliable and advanced equipment and solutions in China,and provide you with comprehensive proposals from the beginning .Choose and believe us,we assure you more value added services.

Having Customer Service is very important, but that's just the way it is.

Depending on investment budget and site size