- Home

- Solution

- Products

- Services

- Blog

- About

- Contact

Juice production line is used for all kinds of fruit deep processing into delicious juice drinks, with the development of globalisation, each country's support for deep processing of agriculture is greater, juice drinks to become the mainstream is the development trend of beverages. At present, the common fruit juice drinks on the market are: orange juice, mango juice, pineapple juice, strawberry juice, blueberry juice, apple juice, pear juice, kiwi juice, sea buckthorn juice, passion fruit juice, fruit juice tea drinks, etc., and according to the characteristics of the fruits as well as the market positioning of the selection of different products, we provide a complete set of solutions for juice production lines with different outputs ranging from 2,000BPH to 48,000BPH.

According to the different content of fruit juice, it is generally clear juice or turbid juice products made by adding water, sugar solution, acidifier and other modulations in fruit juice or concentrated fruit juice. The content of fruit juice in the finished product is not less than 10%. Fruit drinks with juice content of not less than 5% in the finished product, can be divided into natural fruit juice production line (fruit as raw material), with pulp beverage production line, blending fruit juice beverage production line (concentrated fruit juice as raw material).

According to different packaging, it is generally divided into PET plastic bottle juice production line, glass bottle juice production line and can juice production line, tetra pack juice production line.

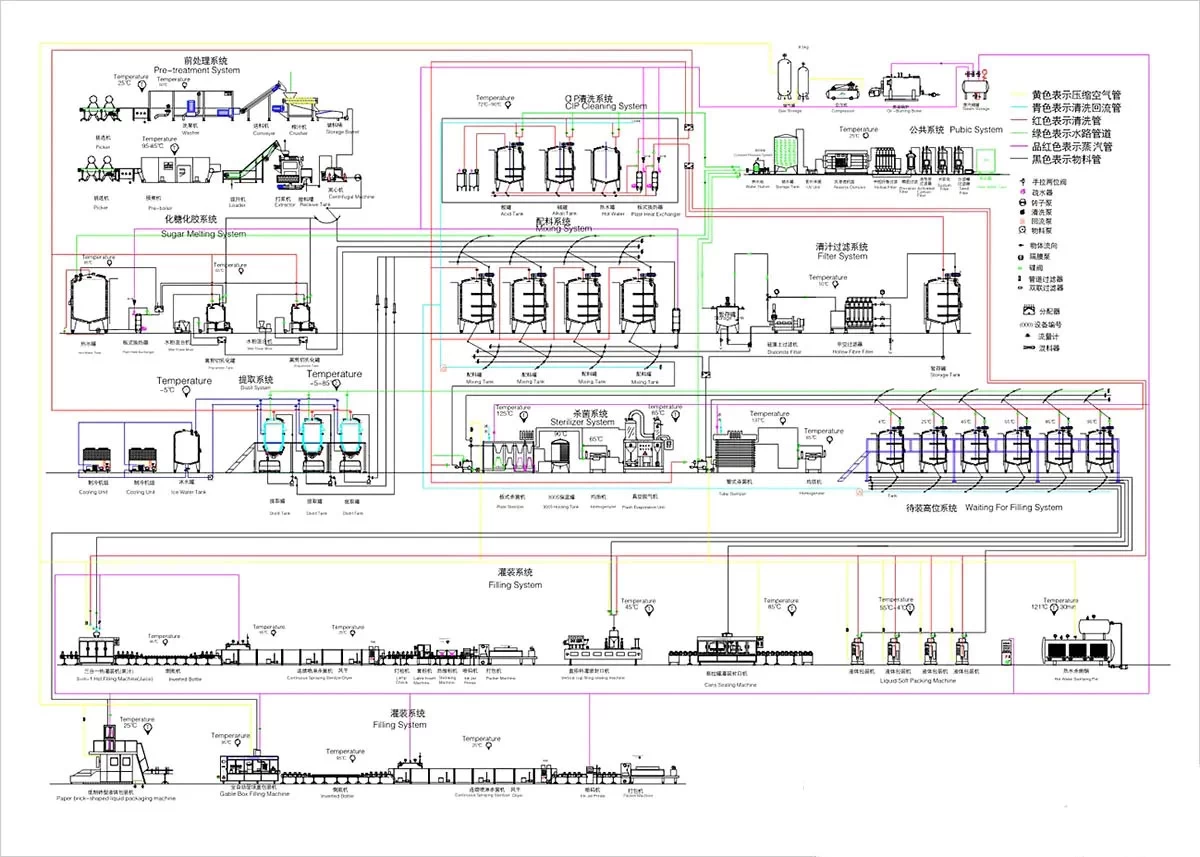

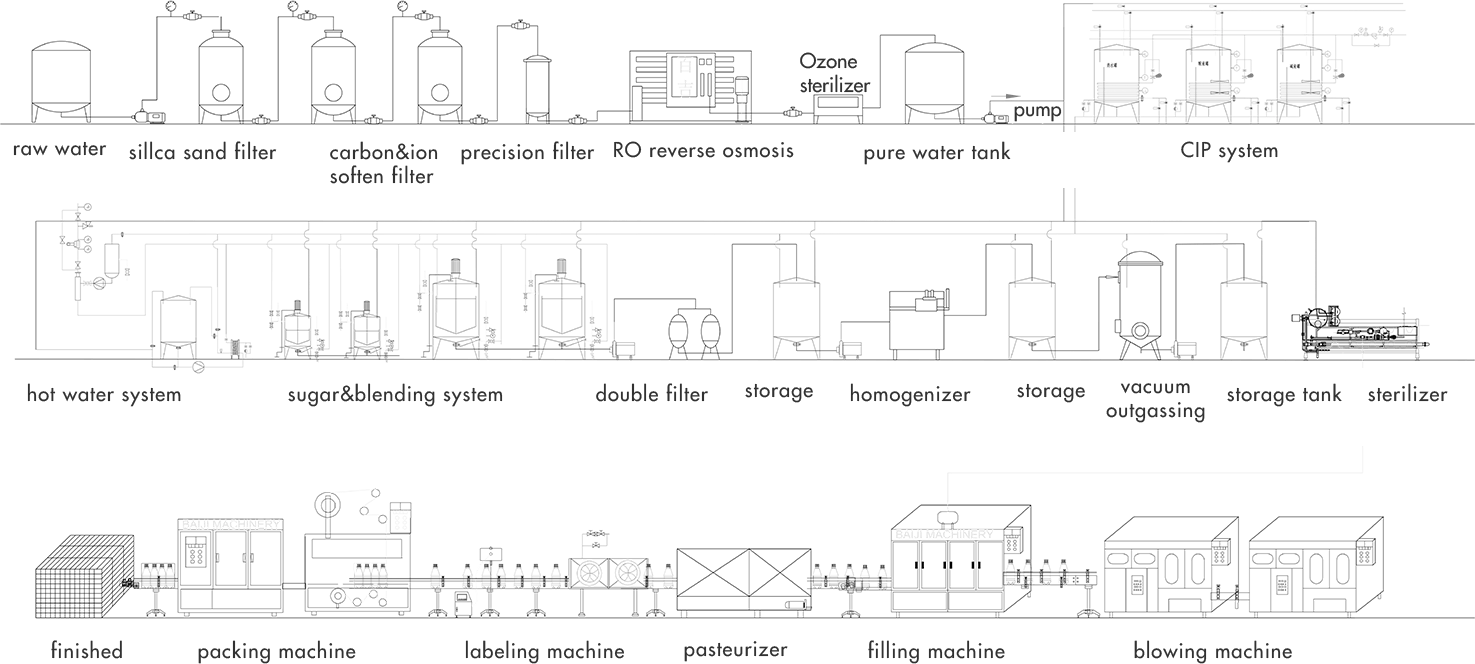

Juice Drink Production Line Process Flow Introduction:

Fresh Fruits - Cleaning - Fruit Selection - Spraying - Fruit Inspection - Preheating - Juice Extraction - Filtration Clarification - Filtration - Blending - Sterilisation - Aseptic Filling - Tunnel Sterilisation - Cooling - Blow-drying -Packaging.

Fruit juice beverage production equipment:

cleaning (washing machine) - fruit inspection (fruit inspection machine) - crushing (crusher) - pulping (pulping machine) - juicing (juicer) - filtration (filter) -Concentration (concentrators) - Blending (blending tanks) - Sterilisation (sterilisers) - Aseptic storage (aseptic tanks) - Aseptic filling - Secondary sterilisers -labelling machines - coding machines - automatic packaging machines - palletising machines

According to the positioning of juice products and different production processes, the equipment used is also slightly different, Comenster team to provide you with professional juice production line solutions, according to your market positioning, product characteristics, we provide from the juice product development and design, juice production line design, planning and design of the whole set, bottle design, packaging options, marketing and other comprehensive all-round services.

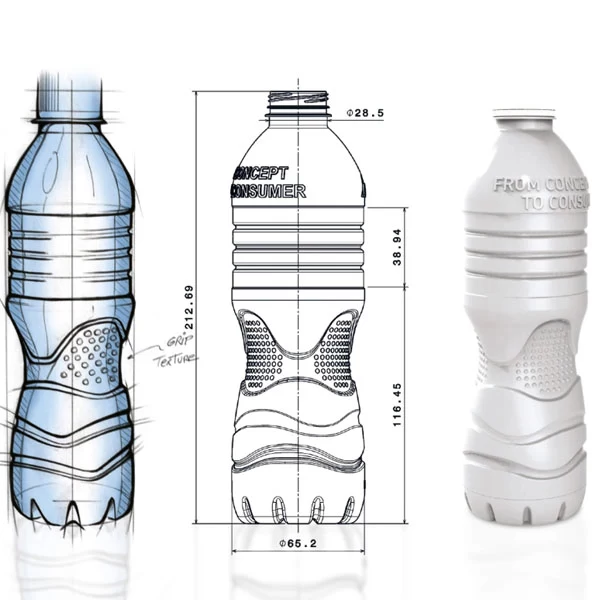

Bottle Type design:

Comenster professional technical team, according to your needs for free bottle design, for you to recommend the right bottle structure, to increase the competitiveness of your products in the market, and at the same time according to the market situation of your country for you to recommend the right bottle type.

According to the different needs of customers and bottle drawings, customize the filling and packaging equipment scheme.

As shown below:

We can supply bottle preform, caps, label rolls with very reasonable price.

Choose the right production line according to the fruit category:

Orange juice production line

Mango juice production line

Pineapple juice production line

Apple juice production line

Blueberry juice production line

Blackcurrant Pressed Juice production line

According to the juice production process to choose the right production line:

Aseptic Cold Filling Juice Production Line

Hot Filling Juice Production Line

According to the juice packaging form to choose the right production line:

PET plastic bottle juice production line

Glass bottle juice production line

Easy-pull juice production line

Tetra Pak Juice Production Line

Bag Juice Production Line

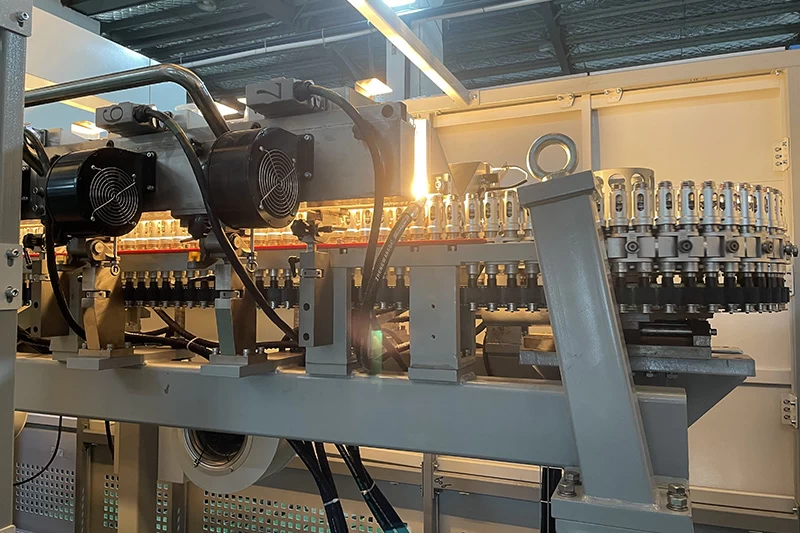

Comenster Machinery is one of the leading juice production line manufacturers and suppliers in China, serving and meeting the growing demand for high quality juice products. Our production lines are centrally controlled, technologically advanced, and require high precision to ensure that the juice is processed efficiently, effectively and reliably, and our juice production line has a full set of equipment for juicing, filtering, mixing, sterilising and packaging, which can meet different production requirements.

We cater to a wide range of applications including extraction and processing of fruits, vegetables and other ingredients, high concentration fruit juice concentrates, etc. to produce quality fruit juices that meet international standards. As a trusted factory, we ensure the use of quality materials and adhere to stringent quality control standards to provide the best juice production line solutions. Our experienced technicians and engineers provide quality customer support, installation and commissioning services, and troubleshooting services to ensure prompt and reliable operation of the equipment. If you are looking for a reliable juice line supplier in China, Comenster Machinery is your first choice. For more information about our products and services, please contact us.

Having Customer Service is very important, but that's just the way it is.

Depending on investment budget and site size