- Home

- Solution

- Products

- Services

- Blog

- About

- Contact

Comenster is a leading manufacturer of bottled water equipment, specializing in PET plastic bottled water production line design. We will plan your overall bottled water production line, from the source water treatment to the final product packaging, according to your different water quality reports. Our production lines can process between 6,000 and 76,000 bottles per hour.

We will provide you with a complete set of solutions from A to Z, including a water treatment system and a preform injection molding machine, blowing machines, filling machines, film wrapping machines, carton box machines, conveyor systems, as well as package production-related raw materials, such as preforms, caps, plastic particles, labels, shrink film, cartons, etc. Our comprehensive offering extends from the initial plant planning stage to after-sales installation and commissioning services.Choose Comenster, we provide you with more additional services, is your trusted global partner, to help you purchase more quality equipment.

Access to clean water is essential for maintaining human health and well-being. There are numerous sources of drinking water, which require different treatment processes. We provide a comprehensive range of solutions for various water sources, including water treatment systems, injection systems, blowing machines, filling machines, packaging machines, conveyor systems, electrical systems, cables and wires, and the relevant raw materials, such as preforms, caps, plastic particles, labels, shrink film, clean room building materials, and more. In addition, we provide a complete service from start to finish, including pre-sale planning drawings, post-sale installation, commissioning, and maintenance. The following is a list of the types of previous customers we've had the pleasure to work with:

1. If you'd like to make the same product, we can provide samples of our overall project plan for your reference.

2. If you'd like to make a different product, we're happy to work with you to create a new overall project plan.

Mineral water

Spring water

Sparkling water

Soda water

Coconut waterr

Hydrogen water

A. Treatment System for pure water bottling line

Raw water--Pump--Silica sand filter--Carbon filter--Water softner--Reverse Osmosis -UV sterilizer-Ozone generator--Finished water tank

B. Treatment System for mineral water bottling line

Raw water--Pump--Silica sand filter--Carbon filter--Water softner--Micro filter--Ultrafilter device -UV sterilizer--Finished water tank

Features:

Use high quality stainless steel for tanks, pipes and connectors.

Online type pressure auto self-protection device.

System safe protecting and alarm system.

This stretch automatic blow molding machine is designed for automatic feeding from preform to bottle, eliminating the need for human intervention throughout the entire production process. The machine is equipped with different number of cavities, allowing for flexible production capacity.

Production capacity: 2400BPH-24000BPH

Bottle volume: 100ml-2.5L

Large capacity blow molding machine: 3L-20L, applicable with barrel water production line

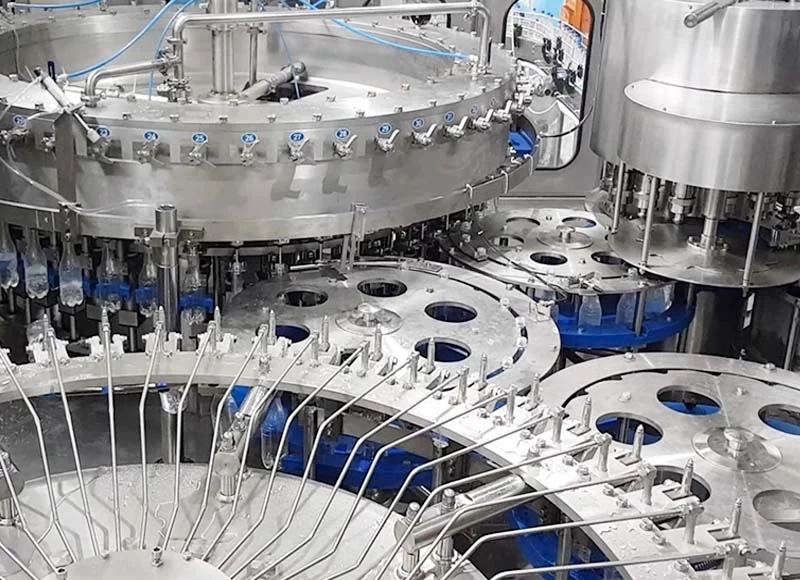

The water bottling machine has been designed with a three-in-one structure, offering a compact and simple operating system. Its automated operation ensures a high level of efficiency, bottle cleaning before filling, remove contamination after the liquid level filling. The filling level can be automatically adjusted according to the situation, and the bottle cap is attached using a capper or rotary capping, providing high production efficiency.reatment System for pure water bottling line

Application range: PET and glass bottles, aerated and non-aerated beverages, cans, etc.

Bottle volume: 200ml-2.5L

Capacity: 2000BPH-36000BPH

The marketing of bottled water is primarily focused on the outer packaging and bottle labeling. We offer a range of labeling options to suit different bottle designs. The current standard for bottled water labeling equipment is as follows:

Sleeve labeling machine: suitable for small bottled water equipment production line, as well as beverage production line, the bottle for the whole body sleeve labeling, is conducive to marketing and corporate publicity.

Hot melt OPP labeling machine: suitable for medium and large bottled water production line, high output, bottle labeling effect is neat.

Self-adhesive labeling machine: for the middle and high-end customized water, label design is beautiful, labeling effect is better.

For different packaging specifications and packaging forms, using different packaging equipment, mainly as follows:

Film wrapping machine: PE film is used for packaging, packaging specifications can be customized into 3x4, 2x3, 4x6 and other different specifications.

Carton machine: mainly used for bottle cartoning, specifications can be customized.

Film wrapping machine for finished cartons: the second film wrapping for finished cartons, the appearance of the package is neat and tidy, while avoiding damage to the outside.

Comenster offers the complete line solutions of water,beverage,milk,beer,edible oil and cosmetic manufacturers and so on: process technology,bottle blowing technology,filling technology and packaging technology and other marketing services.We promise you the most reliable and advanced equipment and solutions in China,and provide you with comprehensive proposals from the beginning .Choose and believe us,we assure you more value added services.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod.

Nemo enim ipsam voluptatem, quia voluptas sit, aspernatur aut odit aut fugit, sed quia consequuntur magni dolores eos, qui ratione voluptatem sequi nesciunt, neque porro quisquam est?

Consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Quis autem vel eum iure reprehenderit, qui in ea voluptate velit esse, quam nihil molestiae consequatur, vel illum, qui dolorem eum fugiat, quo voluptas nulla pariatur?

Nam libero tempore, cum soluta nobis est eligendi optio, cumque nihil impedit, quo minus id, quod maxime placeat, facere possimus.

Nemo enim ipsam voluptatem, quia voluptas sit, aspernatur aut odit aut fugit, sed quia consequuntur magni dolores eos, qui ratione voluptatem sequi nesciunt, neque porro quisquam est?