- Home

- Solution

- Products

- Services

- Blog

- About

- Contact

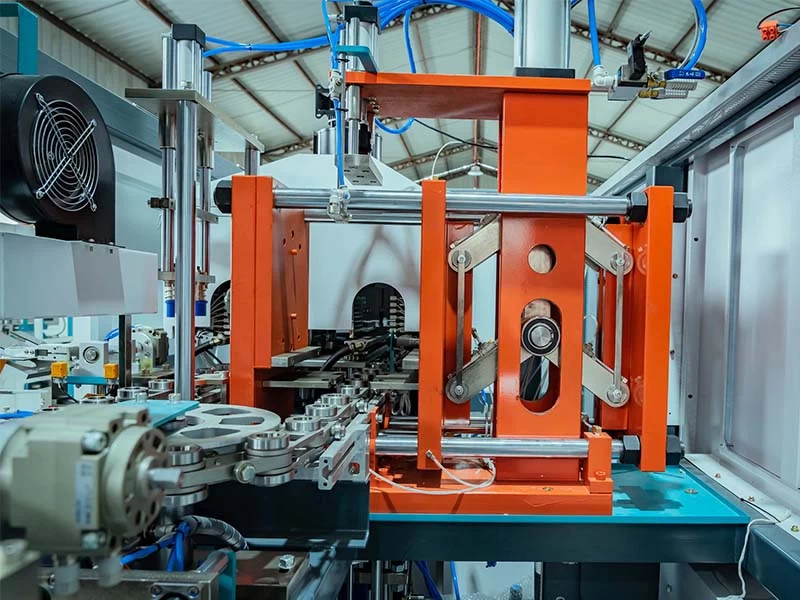

CM Automatic Blow Molding Machine is an advanced equipment

designed for efficient production of all kinds of plastic bottles,

which is widely used in beverage, cosmetic, pharmaceutical and other industries.

Its excellent performance and stable quality make it a leading product in the market.

Production capacity: 2400BPH

Bottle volume:100ml-5L

High efficiency and stability, simple operation, fully automatic equipment

Automatic bottle blowing machine is suitable for producing PET plastic containers and bottles of various shapes.

Saving labor: preform automatic lifter reduces labor cost.

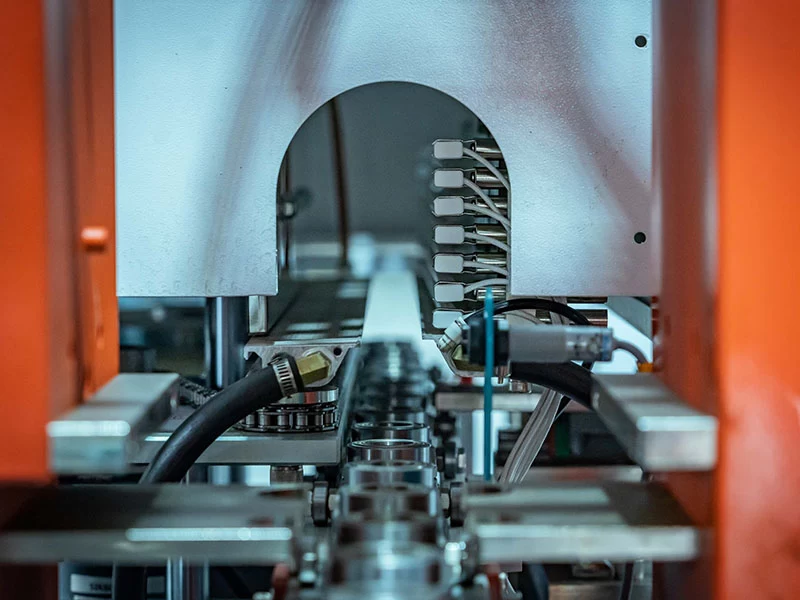

Uniform heating: preheating of bottle blanks by self-rotation and infrared rays ensures uniform heat distribution and improves molding rate and production.

Precise control: Perfect preheating of preforms is realized by PLC voltage adjustment, maintaining constant temperature and humidity.

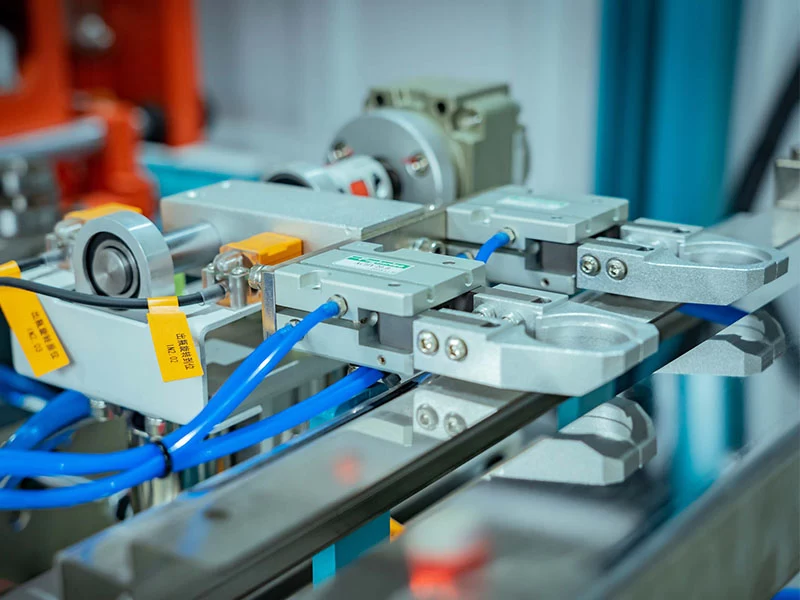

Automatic operation: Adopting PLC imported from Japan and Delta control panel, easy to operate and stable performance.

Modularized design: maintenance and repair are easier.

Production capacity increase: Stable performance and increased production per unit time. Precise positioning: three templates design, accurate mold positioning, solve the problem of high-speed use.

Safe and reliable: Unique valve position design, easy to understand the pneumatic diagram of the machine.

High efficiency and low cost: Fully automatic process, low cost, high efficiency, easy to operate and maintain.

Flawless Finished Product: Ideal cooling system ensures flawless bottles, easy installation, testing and start-up, scrap rate below 0.2%.

Ease of operation: high degree of automation reduces manual intervention and operational complexity.

Cost-effectiveness: Low maintenance costs and high productivity help companies improve profitability.

Product Consistency: Ensure consistency and high quality of each bottle, reducing scrap rate.

Item | Model | Unit | CM2-2400 |

Molding group specifications | Number of cavities | cavities | 2 |

Molding force | KG | 15000 | |

Mold stroke | mm | 100 | |

Tie bar stroke | mm | 370 | |

Bottle mold stroke | mm | 50 | |

Bottle spacing | mm | 100 | |

Heating spacing | mm | 100 | |

Preform count | PCS | 40 | |

Bottle specifications | Maximum bottle capacity | ltr | 0.75 |

Neck bottle (outer diameter) | mm | 32 | |

Maximum preform height | mm | 100 | |

Maximum bottle diameter· | mm | 70 | |

Maximum bottle height | mm | 240 | |

Electrical control specifications | Number of light boxes | UNITS | 1 |

Number of lamps | PCS | 14 | |

Power consumption | KW | 10 | |

Total power capacity | KW | 28 | |

Voltage | Voltage | 380V/50HZ | |

Air compressor specifications | Operating pressure | kg/cm2 | 7 |

Blowing bottle pressure | mpa | 30 | |

High-pressure gas consumption | L/min | 1200 | |

Low-pressure gas consumption | L/min | 2000 | |

Installed power | KW | 28 | |

Cooling water specifications | Temperature range | °C | 30 |

Pressure | Mpa | 0.3-0.5 | |

Flow rate | L/min | 150 | |

Rated power | KW | 3 | |

Machine specifications including elevator | Host dimensions(L×W×H) | M | 2×1.5×2.3 |

Machine weight | KG | 1500 |

Our customers speak highly of the stability and efficiency of the blow molding machine, helping them to stand out in a competitive market.

Efficient and Stable Performance

"Our productivity has increased dramatically after using this blowing machine. The machine runs smoothly and is virtually trouble-free. Really recommendable equipment!"

Excellent production quality

"The bottles produced with this machine are of very high quality, with a smooth surface and no defects. We are very satisfied with the final product."

For more product information or for customized solutions, please feel free to contact our sales team. We look forward to working with you to advance the industry.