- Home

- Solution

- Products

- Services

- Blog

- About

- Contact

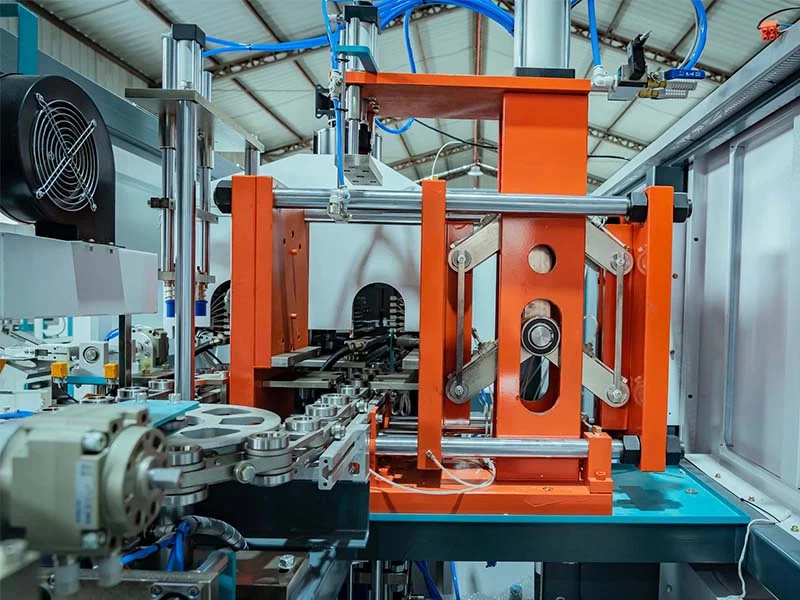

The cosmetic bottle blowing machine is divided into two types:

automatic and semi-automatic.

The automatic model is fully automated and features an automatic preform loading machine,

and a flexible robot hand that can be operated automatically to remove the bottle.

The semi-automatic model requires manual insertion of preforms,

which increases the labour intensity of workers and the cost of production.

Comenster manufacturers advise you purchasing a fully automatic blowing machine.

Production capacity:2000-12000 BPH

Comenster machinery Ltd. is a leading manufacturer of professional cosmetic bottle blowing machines. Our series of blowing equipment is widely used in the production of PET plastic, which is used as a raw material for various shapes and capacities of cosmetic bottles.Each bottle blowing machine is manufactured and assembled according to standardization, which ensures the unity of parts, stability of the machine, easy operation and easy maintenance.

Description:

1. Mold unit

The clamping part is highly durable and has low variation, improving the stability of the machine. Engineering software analysis and optimization of the clamping system guarantees fast movement and superb rigidity. The mold clamping unit with high pressure compensation design guarantees perfect quality of the final PET bottles.

2. Infrared Heating System

The advanced air circulation heating design keeps the temperature accurate and uniform, which is the key to producing high-quality plastic bottles. The oven is equipped with adjustable lamps, allowing for the drying tunnel to be adapted to various sizes of preforms.

3. Preform Loading and Bottle Discharge System

The automatic preform elevator reduces manual intervention and production costs, while the pneumatic components ensure reliable performance and long life of the machine. The linear slide rails increase the speed of movement. The standardized design of the robot hands can be quickly changed according to different bottle opening.

4. Stretching system

The machine is equipped with a servo stretching system, which ensures fast stretching and a long stretching distance. The linear slide rail provides a smoother and faster stretching action.

Characteristic:

This new model offers enhanced production efficiency.

This machine is suitable for the production of PET bottles with a capacity of between 50ml and 5L. The machine is equipped with an advanced PLC control system and a touch panel for easy operation.

The PLC system has the capacity to store up to 30 sets of blowing parameters.

The machine is equipped with a reliable multi-sensor system that monitors its fully automatic functioning.

The machine is equipped with a special air storage unit.

The precise infrared heating unit with lamps allows for easy mechanical adjustment.

The cooling system provides an effective cooling effect.

The compact design allows for optimal use of space.

The installation and operation of this product are easy.

The machine is operated via a full-automatic man-machine interface, which is easy to use and ensures smooth running. There are few faults and the blowing speed is fast.

All parts of the machine have been selected, precision-machined and finished to a high standard. The continuous preform loading mechanism has been designed to be highly compatible with preforms, ensuring smooth and continuous loading, high speed and high efficiency.

The use of a servo motor for stretching preforms ensures a fast stretching speed, accurate stretching stroke and the ability to set the stretching stroke arbitrarily.

The bottle can be conveyed directly to the filling line with a novel conveying mechanism that ensures smooth and reliable transportation.

Professional PET plastic bottle automatic blowing machine manufacturer in China

Comenster machinery and equipment manufacturers have the full range of production equipment, mature technology, and parts processing technology to reach the advanced level. We can design the machine, choose the configuration and auxiliary equipment according to the special production requirements of the customers to meet the actual production needs of the customers.