- Home

- Solution

- Products

- Services

- Blog

- About

- Contact

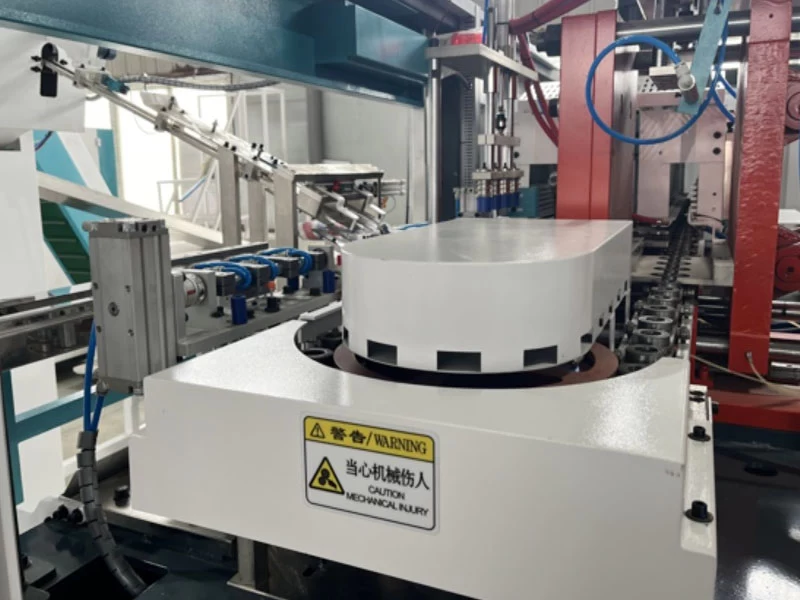

Comenster 4 cavity automatic pet blow molding machine is the most stable two-step

automatic blowing machine in our company, which is suitable for blowing carbonated

beverage bottles, mineral water bottles, cosmetic bottles, large calibre bottles, high-

temperature-resistant bottles and other packaging containers of any shapes made of

PET, PP and other plastics as raw materials.

Production capacity:6000BPH

Bottle volume:100ml-20L

High efficiency and stability, simple operation, fully automatic equipment

A pet bottle blower machine is a widely used equipment for the production of plastic containers. Due to the plasticity of plastic, it makes the manufacturing of pet bottle blower machine easier and more convenient. The pet bottle blower machine is mainly divided into two parts: injection moulding machine and bottle blowing machine, in which the blowing machine is the key component for blowing thermoplastic plastic into bottles.

The working principle of the bottle blower machine is as follows:

1. Preform conveying: The preformed preforms are put into the mould, which is rotated to heat them.

2. Blowing Expansion: Through the blowing system, the heated plastic preforms are expanded into bottles of the required shape.

3. Cooling and curing: The blown bottle is fed into the cooling system and cooled quickly to maintain the desired shape, finally completing the manufacturing process.

1. Full-automatic man-machine interface, easy to operate, the whole machine runs smoothly, less failure, fast blowing speed.

2. All parts of the machine are made of reasonable materials, precision machining and fine surface treatment.

3. Adopting automatic preform loading mechanism, the compatibility of this mechanism for preform is large, the preform loading is smooth and continuous, fast and efficient, overcoming the shortcomings of the traditional robot intermittent preform loading.

4. The heating area is densely arranged with infrared lamps, which has high heating speed, strong penetrating power, even heating, and high efficiency and energy saving of 40%.

5. Imported chain is used in the heating area, which has precise pitch and is durable.

6. The chain in the heating area is designed with mould spring flexible tensioning mechanism to prolong the service life of the chain.

7. PET type bottle blowing machine is equipped with cold air blowing device at the bottle mouth, which can protect the threaded mouth of preform more effectively.

8. The preform delivery mechanism are imported servo motors and electric positioning system, fast delivery of preform, repeat positioning accuracy, to overcome the shortcomings of the traditional pneumatic delivery mechanism.

9. Cylinder type mould locking mechanism, strong mould locking, smooth and reliable operation.

10. Adopting servo motor to stretch the bottle embryo, fast stretching speed, accurate stretching stroke, stretching stroke can be set arbitrarily.

11. The blowing (exhaust) system adopts the original imported combination valve, with fast blowing (exhaust) speed and long service life.

12. Bottles can be conveyed directly to the filling line, with novel design of conveyor mechanism and smooth and reliable conveyance.

Efficient production:

it can produce up to thousands of bottles per hour to meet the demand of mass production.

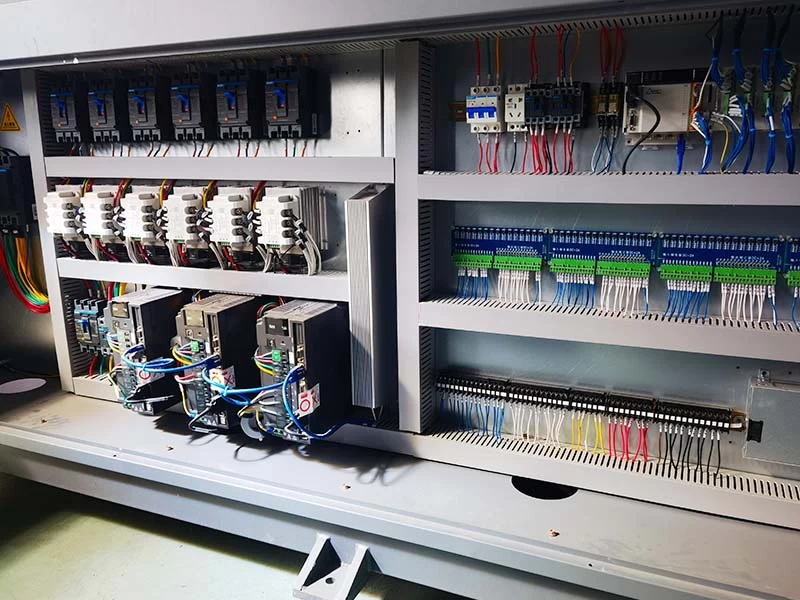

Intelligent control:

Equipped with advanced PLC control system, easy to operate and support multiple parameter settings.

Energy-saving and environmental protection:

adopting the latest energy-saving technology, reducing energy consumption and carbon emission at the same time.

Precise heating:

infrared heaters ensure uniform heating of preforms and improve the quality of finished products.

Modular design:

easy to maintain and upgrade, minimizing downtime.

| Model | Unit | CM4-6000 |

Forming group specification | Mold cavity number | cavities | 4 |

Mould Clamping Force | KG | 40000 | |

Mould stroke | mm | 100 | |

Tie Rod Stroke | mm | 240 | |

Bottom mould stroke | mm | 50 | |

Bottle spacing | mm | 80 | |

Heating spacing | mm | 80 | |

Number of preform head | PCS | 90 | |

Bottle specification | Maximum bottle volume | ltr | 0.7 |

Bottle neck(external diameter) | mm | 38 | |

Maximum preform height | mm | 100 | |

Maximum bottle body diameter | mm | 70 | |

Maximum bottle body height | mm | 240 | |

Conceptional production capacity 500ml 14g | B.P.H | 6000 | |

Electrical control specifications | Light box number | Unit | 4 |

Light number | pcs | 24 | |

Use power | KW | 20 | |

Total power capacity | KW | 48 | |

Voltage | Voltage | 380v/3phase | |

Air pressure specifications | Operation pressure | kg/cm2 | 5 |

Bottle blowing pressure | mpa | 3 | |

High pressure air consumption | L/min | 4000 | |

Low pressure air consumption | L/min | 0 | |

Configuring power | KW | 44 | |

Cooling water specifications | Temperature range | °C | 10-15 |

Pressure | Mpa | 0.3-0.5 | |

Flow | L/min | 80 | |

Power rating | KW | 10 | |

Machine specifications including hoist | Host size(L×W×H) | M | 5*3.5*2.5 |

Machine weight | KG | 5000 | |

Our machine has one year warranty time.We provide customers technical support.Comenster bottle blow molding machine manufacturer and supplier can assure you of high-quality blow molding and a quick and efficient start to production with our machines.