- Home

- Solution

- Products

- Services

- Blog

- About

- Contact

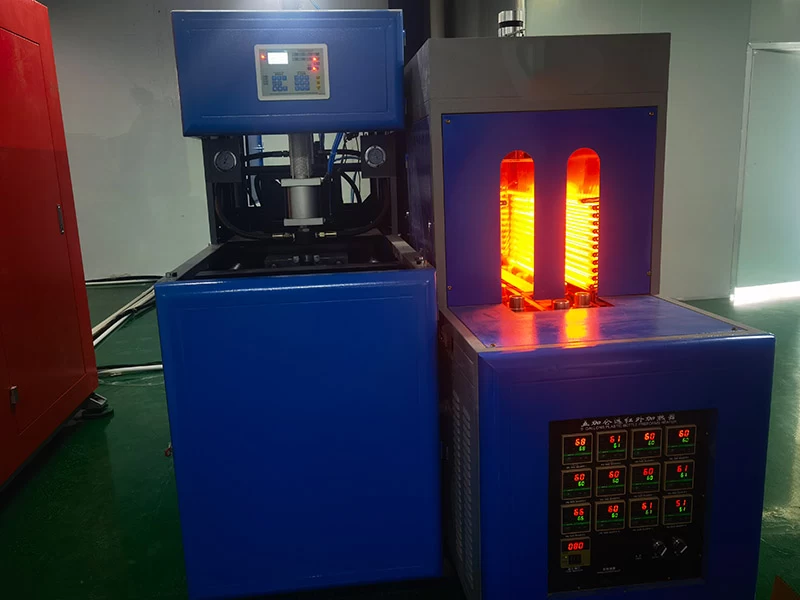

Comenster semi-automatic bottle blowing machine is an efficient machine

designed to meet the needs of small and medium scale production.

It balances productivity and cost-effectiveness through its semi-automated mode of operation,

and is suitable for the production of plastic bottles, jars,5 gallon barrels and other various bottle types.

Whether you are in the food and beverage, cosmetic or pharmaceutical industries,

you can rely on our semi-automatic blow molding machines to boost productivity and product quality.

Scope of application: Cosmetics industry,Food and Beverage industry, Personal care

products, Pharmaceutical industry, Cleaning products.

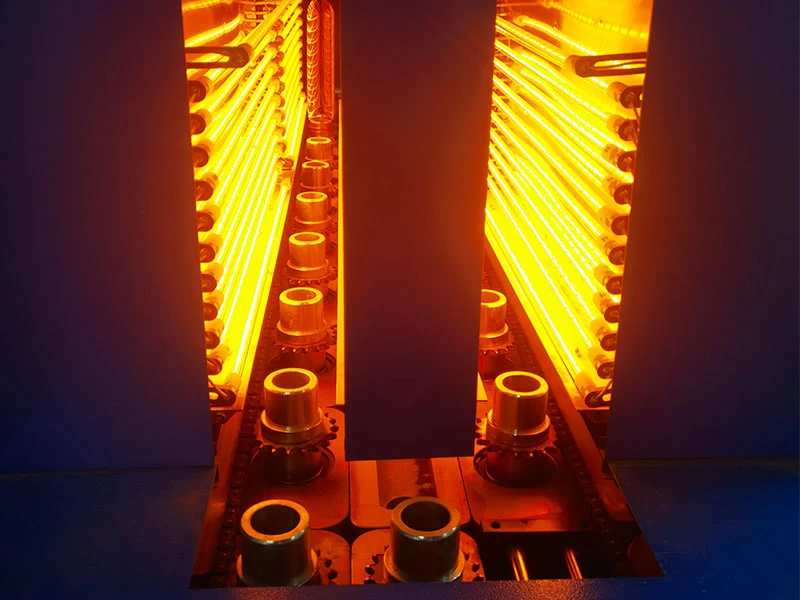

Infrared multi-functional plastic bottle blank heater is three-phase four-wire 380V power supply (also available 220V power supply), the machine is divided into seven layers of heating lamps, divided into four heating zones, electrical box is equipped with electric heating control components, the boot preheating time is generally 5-8 minutes or so, the temperature is transported by the electric heating couples to the temperature controller for automatic temperature control, so that the temperature inside the heating box is stable and controlled, the infrared light penetration is strong, fast and reliable, to ensure that bottle blanks have the desired heating effect, put the bottle blank cycle heating a circle after production, the specific temperature is adjusted according to the needs of bottle forming. Uniform, fast and reliable, to ensure that the preforms have the ideal heating effect, put the preforms circulating heating circle for production, the specific temperature according to the bottle molding needs to be adjusted.

Oven: The preforms are heated uniformly to a temperature suitable for blow moulding. Infrared heaters are usually used to ensure that the preforms are heated uniformly in the axial and circumferential directions.

Blow Mold: The mould is the key tool for shaping the final shape of the PET bottle. The mould is designed according to the desired shape of the bottle and after closing, the preheated preform is blown inside the mould with high pressure air.

Air compressor system: Provide the required air for the blow molding process, to achieve the expansion of the bottle embryo and close to the blow mold, forming the key factors of the final bottle shape.

Control System: The control system is the brain of the blow moulding machine, through PLC and touch screen interface, it can accurately control all the operating parameters and production process of the machine to ensure product quality.

Cooling System: After blow moulding, the cooling system will cool the PET bottles to fix the shape and improve the production efficiency.

1. All the machines are of improved design, which are up to IS9001 quality system and CE standard.

2. Controlled by microcomputer, it can control the involved technical parameters more accurately.

3. Simple and safe operation, only one person is needed and no special training is required.

4. Semi-automatic bottle blowing machine can blow PET carbonated beverage bottles, mineral water bottles, cosmetic bottles, pesticide bottles, oil bottles and so on.

5. The whole machine has low power consumption and high production capacity, which greatly reduces the operation cost and improves the production efficiency of customers.

6. Advanced PLC control system, time control can be accurate to 0.01 seconds special air storage device, the use of infrared lamp heating, strong penetration, the bottle embryo rotating heat, rail rotation, heating uniformity, fast and reliable.

7. Different heating lamps are equipped with an independent temperature control device, to ensure that the bottle embryo has the ideal heating effect, the direction of the heating lamp can be adjusted according to the different embryo bottles, the operation of the operation of one person, no special training. Only one person is needed to operate the machine, no special training is required.

8. Easy installation and startup, the scrap rate of finished products is less than 0.2%.

9.The semi-automatic bottle blowing machine adopts advanced pneumatic system and heating technology to ensure excellent bottle molding. Highly efficient production capacity can significantly increase your production line output.

10.The equipment structure is well-designed, and routine maintenance and upkeep are easy. In long-term use, the equipment has low maintenance cost, which ensures the efficient and stable operation of the equipment.

1. Save labour cost: hand-inserted automatic bottle blowing machine can realize the automatic production of products without stopping, not only the production efficiency is high, but also can greatly save labour costs.

2. Save production time: hand-inserted automatic blow molding machine automation process can be completed automatically, do not need to spend a lot of time to intervene and control.

3. Production of environmentally friendly and reliable: the use of mould injection molding technology made of excellent product quality, environmental protection and durability.

4. Flexible adaptability: the hand-inserted automatic bottle blowing machine is suitable for a variety of materials, such as PET, etc., and also supports the production of a variety of bottle shapes.

5. Reduce production waste: the production process of hand-inserted automatic bottle blowing machine can avoid many waste problems, such as waste of raw materials, waste of man-hours and so on.

6. Manual preform feeding and bottle dropping. It has the advantages of cost saving, simple operation and safety.

Category | Item | Unit | CM-500 |

The finished product | The raw material | / | PET |

volume | L | 5L | |

The theory of production | Bottle/Hour | 5L-400 | |

1.25L:700-1000 | |||

2.5L: 700-1000 | |||

Maximum height | mm | 350 | |

The largest diameter | mm | 170(1-Cavity) | |

Template size | The biggest template area | mm | 480*340 |

Die thick | mm | 220 | |

Clamping force | KN | 5T | |

Auxiliary equipment | Air compressor | 11KW | ≥3.0/3.0 |

Freeze drying machine | 30kg | ≥3.0/3.0 | |

Precision air filter | 30kg | ≥3.0/3.0 | |

The host power | power | KW | 25 |

Voltage/frequency (three-phase) | V/HZ | 380/50 | |

Machine size | Host size | m | 1.94*0.65*1.7 |

Oven size | m | 1.8*0.6*1.35 | |

Host weight | kg | 750 | |

Oven weight | kg | 230 |

1. Failure of bottle blowing

Possible reasons:

Unstable mold temperature: too high or too low mold temperature will affect the quality of bottle molding.

Heating system failure: heating element or sensor failure will lead to uneven heating.

Insufficient gas pressure: insufficient gas pressure or unstable gas flow will affect the blowing effect.

Solution:

Check and adjust the mold temperature: Make sure the mold temperature meets the production requirements, and adjust the temperature control setting of the heating system if necessary. Check the heating system: Check the heating elements and sensors regularly to make sure they are working properly. Replace damaged parts if necessary.

Check the gas source: Make sure the pressure of the gas source is stable, and check whether the gas pipe is leaking or blocked. Adjust the air pressure to ensure that the gas flow meets the requirements.

2. Abnormal noise of machine operation Possible

Possible reasons:

Wear of mechanical parts: Long-term use leads to wear or loosening of mechanical parts. Insufficient lubrication: Insufficient lubricant or aging leads to increased friction.

Foreign matter interference: there may be foreign matter inside the equipment to affect the operation.

Solution:

Check the mechanical parts: Regularly check the mechanical parts of the equipment, such as bearings, gears, etc., and replace the worn or loose parts in time.

Regular lubrication: According to the instructions for equipment use, add lubricant regularly to ensure smooth operation of all parts.

Clean the equipment: clean the inside of the equipment regularly to remove possible foreign objects.

3. Operating interface failure

Possible reasons:

Electronic control system problems: electronic control system failure leads to the operating interface can not be displayed normally or response.

Software failure: equipment control software error or crash.

Cable connection problems: cable or interface loose, affecting the normal operation of the interface.

Solution:

Check the electronic control system: Check the power supply and connection of the electronic control system, and contact technical support for repair if necessary.

Restart the software: Restart the device control software to see if the problem can be solved. If the problem still exists, it is necessary to contact the technical personnel to deal with it.

Check the cable connection: check the cables and interfaces of the operation interface to ensure a solid connection.

Following over a decade of uninterrupted growth, Comenster has evolved into a comprehensive entity encompassing scientific research, design, manufacturing, and marketing. We are proud to be regarded as one of the industry's leading suppliers of blowing machines. Our company is distinguished by a robust technical expertise, an efficient management system, and a reputation for reliability that has been earned both domestically and internationally. Users commend the machine for its excellent quality, reasonable price, beautiful shape and perfect after-sales system. The bottle blowers are exported to more than 50 countries and regions, including Europe, America, Southeast Asia and the Middle East. A complete set of sales and service systems has been established in these countries.