- Home

- Solution

- Products

- Services

- Blog

- About

- Contact

The 6-cavity automatic bottle blow molding machine has a stable capacity of 9,000

bottles per hour, which is suitable for 12,000 bottled water production line to produce

plastic packaging bottles at high speed. The whole machine adopts modular design,

beautiful appearance, stable performance and high efficiency capacity.

Production capacity:9000BPH

Bottle volume:100ml-20L

High efficiency and stability, simple operation, fully automatic equipment

Widely used in beverage, dairy, detergent, cosmetic and pharmaceutical industries

to meet various market demands.

The entire machine adopts domestic and foreign high-quality raw materials and parts, processing and manufacturing, stable quality,the template and the entire machine are treated with advanced technology such as annealing.All planes and hole positions of the rack are completed in one-time processing in the CNC machining center,ensure that the frame is firm and not deformed, well-balanced, with accurate holes and planes.

(1)Automatic preform return device

It can automatically return poorly arranged preforms to the material bin, eliminating the need for manual sorting, saving labor and time.

(2)Material bin

It is designed with no dead corners, which can ensure that all the preforms are used up and nothing will be wasted.

(3)Gas source recovery system

It can recover approximately 25% of the high-pressure gas. The recovered gas can be used for low-pressure operation of the machine, eliminating the need for a separate low-pressure air compressor system, thus saving investment costs and achieving greater energy efficiency.

(4)Preform sorting device

It can automatically sorting the preforms without the need for any air, relying solely on the weight of the preforms to slide down, which can save one cubic meter of low-pressure air. We also installed an additional cylinder to make it more stable and durable.

(5)Chain

The chain slides using bearings, which is a frictionless suspension structure that allows for smoother operation.

(6)Heating oven

It is centrally heated, which is more energy-saving. At the same time, there are steppers on both sides of it, which reduces the friction between the machines. The entire equipment runs smoothly and makes very little noise.

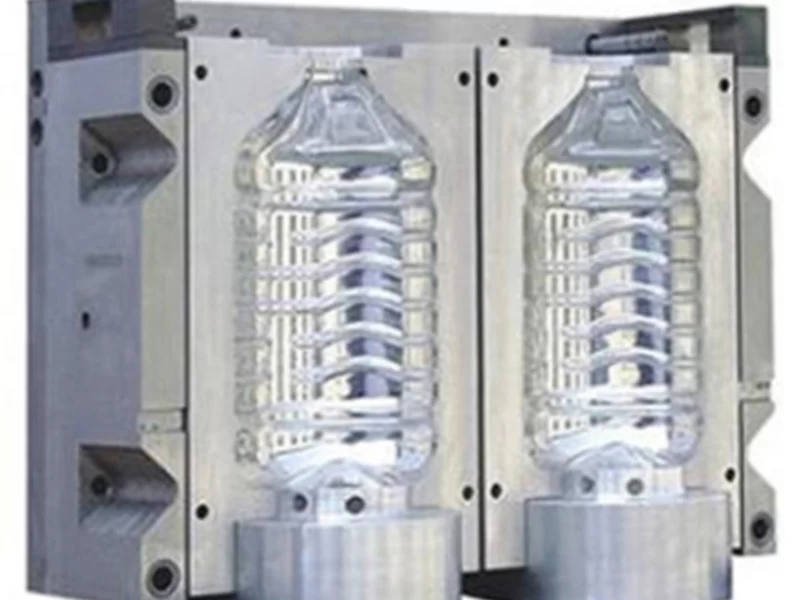

(7)Mould closing structure

It is designed with larger dimensions than our competitors, especially in terms of the reducer and motor and we use high-power components with stronger power.

(8)Oil stick

It can automatically refuel without manual labor. This makes it extremely convenient to use and maintain, saving both time and labor.

(9)Electrical control system/Motion system

Our electrical control system is not a traditional PLC. We are a motion system, more stable and efficient.

(10)English label

Our equipment has a small English label at core part. When the equipment fails, an alarm will appear on the display showing the fault point. The label can quickly locate the physical fault and facilitate to solve problem.

CM-9000 | |

Maximum Bottle capacity | 700ml |

Maximum bottle diameter | Φ68mm |

Neck diameter | Φ18~38mm |

Maximum bottle height under neck | <240mm |

Maximum preform height under neck | <115mm |

Clamping stroke | 90mm |

Bottom mold stroke | 50mm |

Bottle spacing | 76.2mm |

Maximum production capacity (BPH) | 9,000(500ml water bottle) |

Number of cavity | 6 |

Number of heating molds | 6 |

Number of heating lamps | 36 |

Number of preform bases | 120 |

Voltage | 380V |

Frequency | 50Hz |

Consumption power | 30kw/h |

Installation power | 72 kW |

Low pressure | 0 Mpa |

Low pressure air consumption | 0m³/min |

High pressure | 3.5Mpa |

High pressure air consumption | 6m³/min |

Pressure | 2~4bar |

Flow rate | 9m³/h |

Weight | 6500kg |

Main machine (L×W×H) | 5000*1800*2500mm |

Item | Supplier, Origin |

Intermediate relay | OMRON, Japan |

Touch screen | Taida, China |

PLC | |

Motion actuator | ZD, China |

Servo motor | Taida, China |

Servo actuator | |

Exhaust valve | PARKER, USA |

One-way valve | NORGREN, UK/ PARKER, USA |

Pressurizing clamping valve | SMC, French |

Cylinder control valve | |

Machine-hand cylinder |

Excellent after-sales service

"Not only does the device itself perform well, but the manufacturer's after-sales service is also very good. Problems were resolved quickly and the overall experience was very good." -

Low Maintenance Costs

"This blowing machine is designed with maintenance costs in mind, and routine maintenance is very easy and low cost. This is a great advantage for us."

At Comenster, we pride ourselves on providing effective and reliable solutions to our customers. Our experienced engineering team works with each customer to develop a bespoke machine that optimizes processing methods and increases profits. Our expertise, adaptability, robust technical guidance and unwavering dedication to excellence will pave the way to success through automation, superior quality output and enhanced productivity.