- Home

- Solution

- Products

- Services

- Blog

- About

- Contact

The 2-cavity automatic edible oil bottle blowing machine is a two-step

automatic bottle blowing equipment, developed for blowing edible oil bottles.

It is designed to meet customers' demand for large capacity, high speed and

fully automated production. The equipment can also blow other

2L large capacity PET plastic packaging containers, such as carbonated drinks, fruit juice drinks, mineral water, etc.

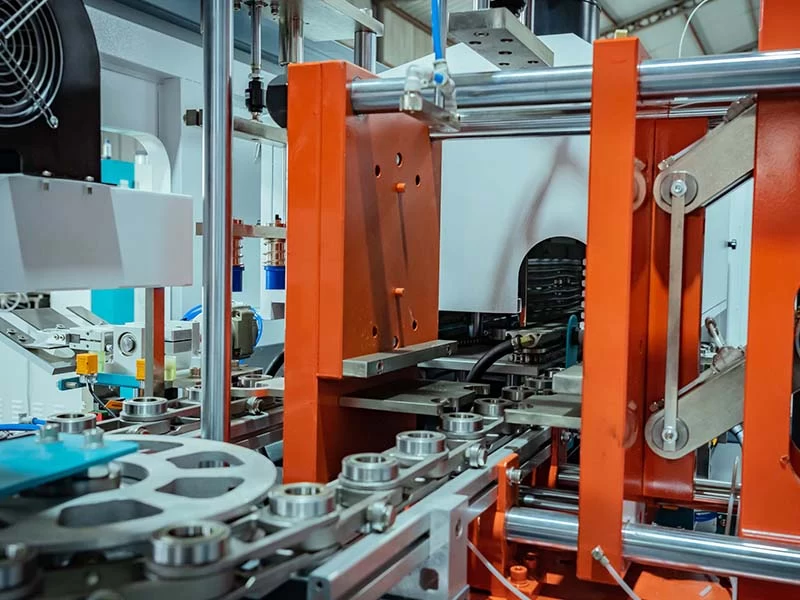

The 2-cavity automatic edible oil bottle blowing machine is a two-step automatic bottle blowing equipment, developed for blowing edible oil bottles. It is designed to meet customers' demand for large capacity, high speed and fully automated production. The equipment can also blow other 2L large capacity PET plastic packaging containers, such as carbonated drinks, fruit juice drinks, mineral water, etc.

Description:

The 2-cavity automatic edible oil bottle blowing machine is a simple, reliable and stable bottle blowing machine with a high success rate of bottle blowing and wide applicability. The machine utilizes high-quality German, Japanese and South Korean products, and the control system is of the second-class PC program circuit. The design is efficient, precise, convenient to maintain and safe and reliable. It is also aesthetically pleasing and durable.

The equipment is easy to operate and maintain. The machine's man-machine interface allows for the remote control and monitoring of its operational status. In the event of a malfunction, the machine will automatically alert the operator, and the man-machine interface will pinpoint the location of the fault, enabling maintenance personnel to address the issue promptly.

The high energy utilization, minimal waste and stable infrared heating system, combined with the highly accurate die close system, ensure quality.

The modular design concept adopted throughout the machine allows for easy maintenance and replacement of parts, reducing the overall maintenance cost.

The open and closing mode, lock mode and bottom mode lifting, among other actions, are integrated, greatly reducing the blowing bottle cycle and improving the output, achieving high efficiency and energy savings.

Range of application: Suitable for blowing PET edible oil bottles.

Characteristic:

Increased production capacity.

Higher energy consumption efficiency.

Operation is stable.

Easy for mould change and repair.

Saves cost.

Gas recovery unit (gas consumption saves by15% -20% ).

Increases production capacity by 20% -30% per unit time.

Power consumption saves 15% -25% (power consumption depends on bottle type).

Servo control to ensure high speed operation and precise positioning of the machine.

Mechanical structure design reasonably covers a smaller area.