- Home

- Solution

- Products

- Services

- Blog

- About

- Contact

PET plastic bottles are a highly versatile packaging material, used in a wide range of

applications including carbonated drinks, drinking water, fruit juice, enzymes and tea drinks

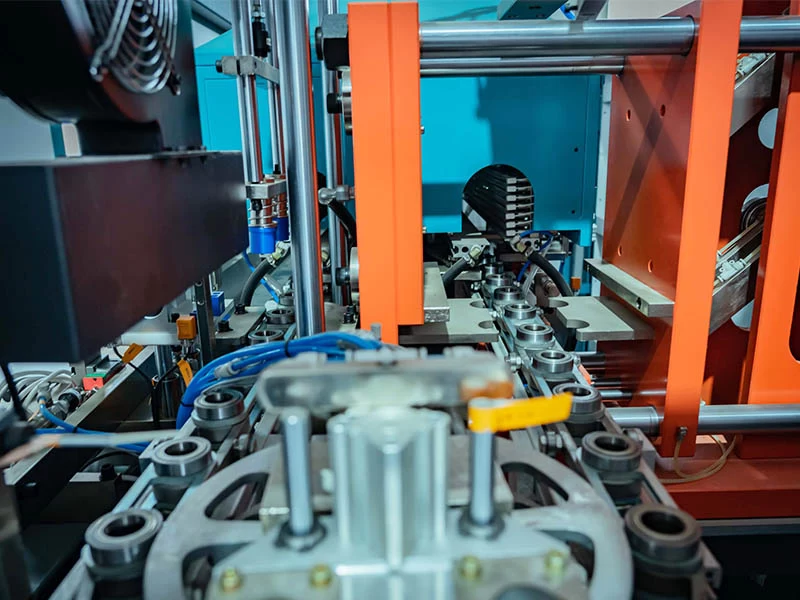

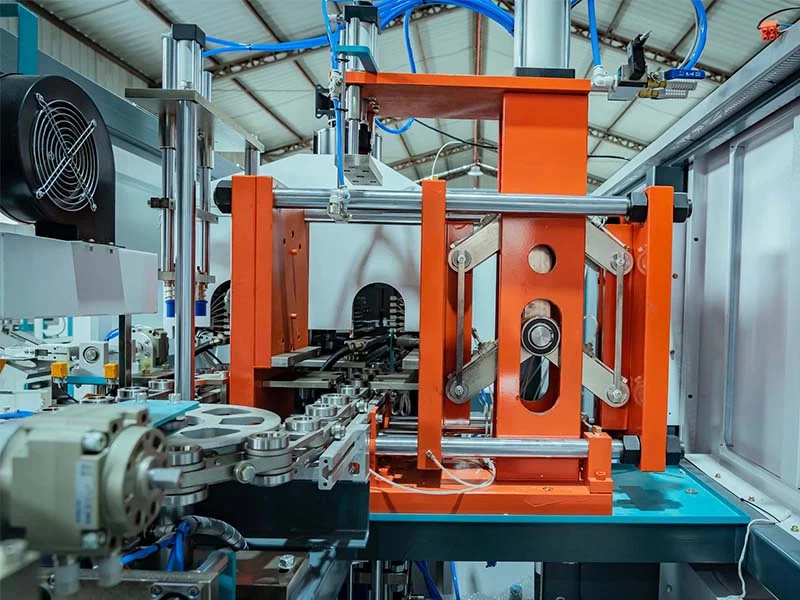

The Comenster fully automatic 2-cavity water bottle blowing machine is suitable for blowing various PET-based plastic bottles, with capacities ranging from 200 ml to 20 litres.

PET plastic bottles are a highly versatile packaging material, used in a wide range of applications including carbonated drinks, drinking water, fruit juice, enzymes and tea drinks – the most common beverage packaging. They are also used extensively in food, chemical and pharmaceutical packaging, as well as many other fields. The Comenster fully automatic 2-cavity water bottle blowing machine is suitable for blowing various PET-based plastic bottles, with capacities ranging from 200 ml to 20 litres.

Full automatic 2 cavity water bottle blowing machine adopts man-machine interface to control all the working procedures, automatic blanking, automatic bottle blowing, automatic bottle, installing magnetic sensing switch, connecting PLC to control the whole procedure to detect each action, traveling to the next action in place to work, travelling to not in place to automatically protect the next action does not work, alarm, PLC to display the location of the fault.

The equipment is capable of high production, with a capacity of 2400 bottles per hour. The heating and blowing cycle is double-action, with independent operation of the mold and sealing, and synchronized bottom mold action.

The bottle blowing effect is excellent, and the mould system is efficient, ensuring a perfect bottle body mould line. The precise bidirectional axial uniform heating ensures the thickness of the bottle, allowing for optimal light blowing.

The machine is capable of high speeds with precise positioning and smooth action.

The cross double curved arm booster lock mode is available for use with the model in question, offering a strong lock force. The opening and closing mould trip can be adjusted according to the size of the product, thereby reducing the opening and closing mould time.

The Far Infrared Heating Tube provides strong penetration and uniform cylinder cylinder rotation heating. Each group of heating temperatures is separately controlled by a PLC or electronic regulator, allowing for precise temperature control. The oven's unique design shortens the drying channel and reduces energy consumption.

The gas circuit design is divided into three parts: micro blowing, high pressure blowing and low pressure action. This allows us to meet the needs of different products. The special high-pressure air recovery device enables the high-pressure blowing bottle exhaust to be recycled, thereby reducing energy consumption.

The operation is divided into manual, automatic program, manual installation and debugging, and automatic normal production. The production process is fully automated, ensuring high-quality products and a clean bottle body. It offers low investment, high efficiency, convenient and safe operation, simple maintenance, and other advantages.

The man-machine interface and the analogue switch operating system are integrated to provide a seamless replacement for the existing system, ensuring a smooth and reliable discontinuous shutdown of the machine.

Water and beverage industry: mineral water, pure water, juice drink,etc

Edible oil industry: large barrel special bottle, other packaging specifications;

Cosmetics bottles: customized molds according to customer requirements, providing diversified bottle type specifications.

Pharmaceutical industry: PET material of alcohol bottles and disinfectant bottles.

Comenster Machinery Equipment Co., Ltd. is a leading manufacturer of bottle blowing machines. The company's technical expertise, cutting-edge production equipment, and advanced testing instruments, coupled with a robust management system, ensure the highest quality standards. Our commitment to excellence, competitive pricing, and comprehensive after-sales support has earned us the trust of both new and long-standing customers. We strive to consistently deliver top-quality products and services that exceed our customers' expectations.