- Home

- Solution

- Products

- Services

- Blog

- About

- Contact

The CM series bottle blow molding machine is available in a range of configurations, with a maximum blowing volume of 0.6 litre or 2.5 litre.

The machine is suitable for blowing any shape of PET-based pharmaceutical,cosmetic ,food wide-mouth bottles and other packaging containers.

The machine is designed for easy operation, with automatic feeding, blowing and discharging. No special technical training is required, and it can produce up to 2000-12000 bottles per hour.

It is highly efficient, cost-effective and stable.

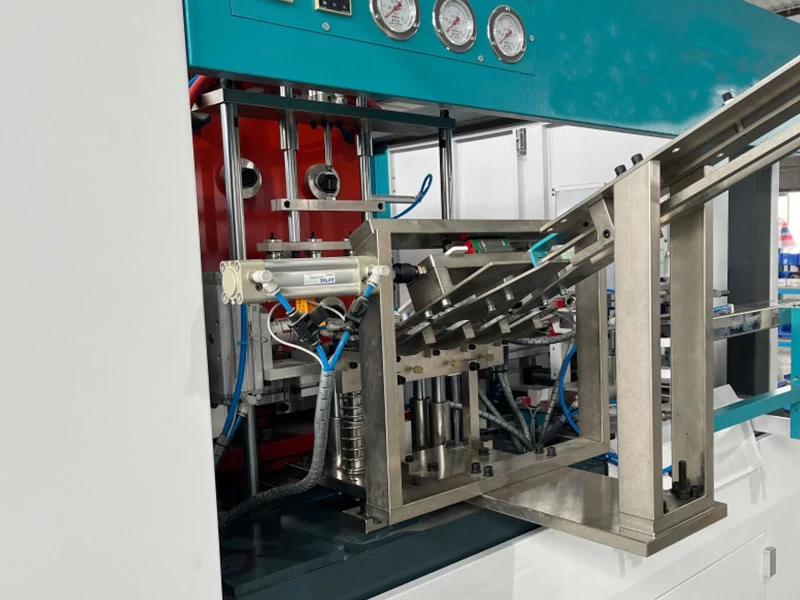

The high-efficiency jar plastic bottle blowing machine is designed for the production of wide-mouth bottles and jars with a capacity of up to 2L. These bottles are commonly used for packaging liquid or semi-solid foodstuffs such as food, beverage, cooking oil and salad dressing, capsules, tablets, honey, canned food, sauces, healthcare products and so on.

Description

Divided into automatic blowing machine and semi-automatic blowing machine, 2L automatic blowing machine without manual labor, automatically loading the preform, high production efficiency, 2L semi-automatic blowing machine is inefficient, take the preform need to be manually operated, low production rate. Wide-mouth plastic bottles offer a number of advantages, including light weight, low breakage rate, high transparency and a competitive price. In today's business environment, the use of wide-mouth plastic bottles can enhance efficiency and convenience, providing easy and quick access to the required food or beverage.

Characteristics

1. The use of a microcomputer control system ensures high stability in machine operation.

2. The machine automatically completes the process of feeding preforms, improving production efficiency.

3. In addition to infrared technology heating, the strong penetration ensures that the preform in the bottle is uniformly and quickly heated.

4. The heating system is designed to be flexible and can be adjusted for different preform structures to adjust the lamp and reflector plate.

5. It is equipped with automatic temperature discharge to maintain a constant temperature environment.

6. In the event of mechanical failure, the built-in safety locking device will be activated immediately to prevent accidents.

7. The action part of the machine adopts the oil pump drive to reduce noise pollution.

8. The air circuit is designed to be separated cleverly, which can satisfy the needs of different links on the air pressure.

9. The high-pressure clamping mould and the double-curved arms improve the effect of mould clamping through the high-pressure mould clamping and double-curved arm linkage design.

Suitable applications

Jar plastic bottles are utilized across a diverse range of industries.

1.Food industry. Wide-mouth plastic food bottles are a primary means of storing and transporting food products, frequently utilized for items such as sauces, jams, preserves, beverages and cooking oils.

2.The cosmetics and personal care industry also utilizes wide-mouth plastic bottles, which are commonly employed as containers for storing and transporting cosmetics and personal care products.

3.The healthcare industry also utilizes wide-mouth plastic bottles for the storage of medicines, pharmaceutical preparations, oral cleansing solutions and other pharmaceutical products.

High efficiency Plastic Jar bottle blow molding machine- Factory, Suppliers, Manufacturers From China

Comenster is dedicated to manufacturing simple, clean, reliable, durable and low-energy-consumption blow molding equipment, with the aim of reinforcing the trust and support of our customers. We provide a comprehensive, one-stop service, together with expert pre-sales consultancy. Our R&D team engages in comprehensive discussions with customers to ensure that our engineering team is equipped to meet their production requirements. Choose Comenster to achieve outstanding performance!