- Home

- Solution

- Products

- Services

- Blog

- About

- Contact

The 5 Gallon Barrel Blow Machine is a crucial piece of equipment in the modern drinking water industry.

The 5-gallon bottled water bottle blowing machine is constructed from high-quality stainless steel,

offering superior corrosion resistance and easy cleaning.

It is equipped with cutting-edge technology and boasts a high degree of automation,

making it the ideal choice for all companies and manufacturers.

2024 Comenster machinery manufacturer is in the production of efficient 5-gallon barrel bottle blowing machine.Our company's expertise lies in the production of 5-gallon bottles and a variety of high-volume PET bottles.The 5-gallon barrel blow molding machine has been specifically designed to produce high-volume plastic bottles. The Comenster 5-gallon bottle blowing machine guarantees the production of durable, high-quality bottles that comply with industry standards.

Description:

The blowing process commences with the loading of preforms into the machine. The preforms are then heated in a dedicated heating system to the required temperature. The heated preforms are then transferred to the blowing unit, where they are placed in the mould. The preforms are then subjected to high-pressure air injection, which causes them to expand and conform to the shape of the mould. Once the bottles have been molded, they are cooled by a dedicated cooling system and ejected from the machine.

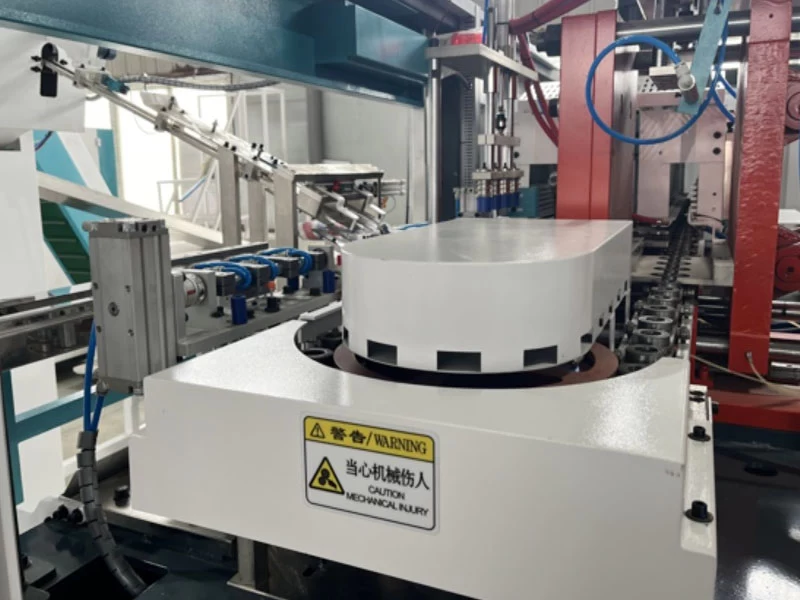

1. The Automatic Preform Lifter is responsible for loading the preforms into the machine.

2. The heating system is responsible for: The preforms are heated to a specific temperature, which softens the plastic and makes it easier to mould.

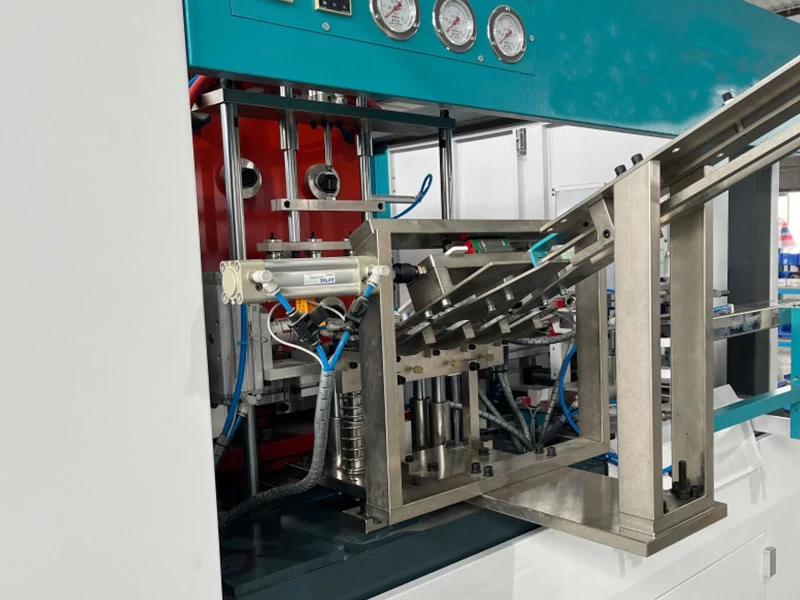

3. Blowing unit: the heart of the machine, the heated preforms are placed into the molds and then blown into the shape of 5-gallon bottles by high-pressure air.

4. The cooling system is responsible for reducing the temperature of the preforms to a level that is suitable for the next stage of the production process. Once the bottles have been molded, they are cured and shaped by the cooling system.

5. Bottle Discharge System: Once the bottles have been formed, they are removed from the mould by a robot hand and collected for further processing or packaging.

6. The heating chain plate is connected to the work station via a stepping cylinder. The photoelectric switch monitors and positions the cylinder, which then blows the material into the product. The stepping cylinder is then promoted to the work station for further monitoring and positioning. This process is repeated continuously, ensuring a seamless and efficient production cycle.

Characteristic:

1. The bottle blowing machine is designed for efficient production, capable of producing a large number of high-quality 5-gallon water bottles in a short time frame, thereby improving overall production efficiency.

2. The bottle blowing machine is equipped with an automated control system, which reduces the need for manual intervention and lowers production costs, offering a high degree of automation.

3. The machine ensures consistent quality by maintaining precise temperature control and utilizing advanced blowing technology.

4. The new blowing machine has been designed with energy-saving technology to reduce energy consumption and meet the requirements of environmental protection.

5. The mould closing part features a reasonable structure design, smooth working operation and large clamping force.

6. The heating system comprises two groups of relatively independent far-infrared lamp ovens. Each group of ovens contains a specific number of far-infrared lamps, which are positioned according to the size of the preforms in order to accommodate different lengths.

7. The rotary chain is driven by an electric motor to ensure continuous operation, thereby facilitating rapid and uniform heating of the preforms within the oven.

8. The use of high-pressure gas in the mould for a defined period allows for the elimination of internal pressure caused by the stretching of preforms, while simultaneously facilitating the formation of a bottle wall that is closely aligned with the mould wall. This process enhances the crystallinity of the bottle body plastic.

The 5 gallon molds

The blow mouling process transforms 5-gallon preforms into 5-gallon pet bottles. The preforms are compact and robust, making them ideal for efficient shipping.

The preforms and 5 gallon bottle

A well-known company with a strong reputation for manufacturing high-quality bottle blowing machines.

The 5 Gallon Barrel Blow Machine is a crucial piece of equipment in the modern drinking water industry. In light of the growing market demand, it is of the utmost importance for companies to select an efficient and reliable blowing machine. Comenster Machinery has become the first choice for customers around the world thanks to its advanced technology and excellent service. If you are seeking a high-quality 5-gallon blowing machine, we recommend a product from Comenster Machinery.