- Home

- Solution

- Products

- Services

- Blog

- About

- Contact

High speed pure water bottle blowing machine

Suitable range: PET bottles from 100 ml to 20 L

Production capacity: 2000 - 12000 BPH (2,4,6,8 cavity optional)

Stable operation performance,energy and cost saving,high efficiency.

Comenster machinery is committed to helping optimize water production lines, saving costs and increasing productivity.

This series of bottle blowing machine is designed for convenience and efficiency, with a large moulding capacity that allows for direct connection to the filling production line.It is suitable for a range of water factories, beverage enterprises and other bottle blowing applications, regardless of scale.This series of bottle blowing machines features a single cylinder drive stretching system, which requires minimal maintenance and is highly energy-efficient.The light box utilizes centralized heating, further enhancing energy savings.The discharge bottle device can be directly connected to the production line, offering a cost-effective solution.The Comenster automatic PET water bottle blowing machine represents the optimal solution for small and medium-sized mineral water and beverage bottle enterprises.

The Comenster CM series water bottle making machine is designed to meet the needs of a wide range of PET water bottle blowing production. It offers a high blowing speed, excellent quality, and high efficiency, with a capacity ranging from 100ml to 20 litres. The number of mould cavities can be tailored to the customer's production capacity, with options of 2, 4, 6 or 8 cavities, to align with varying production requirements.

A small size, low investment, and one-person operation.

Excellent cost performance, simple operation, and easy maintenance.

Its fast machine movement, accurate positioning, and smooth movement minimize the production cost of the machine.

The low scrap rate, fast production speed, stable performance, and extremely easy operation further enhance the cost-effectiveness of the machine.

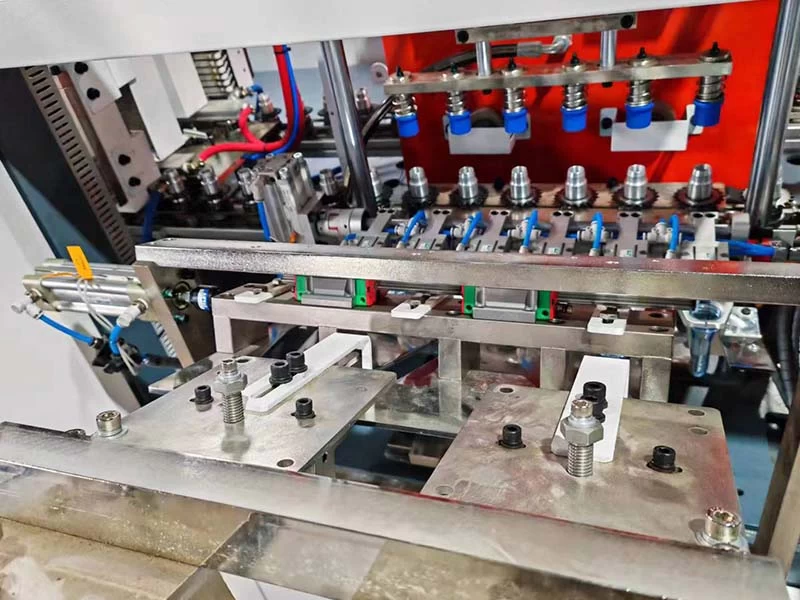

The double-axis curved arm mould locking mechanism is solid and reliable, with a fast running speed and an even far-infrared rotary oven heating system.

The model is equipped with a cross double-curved arm pressurized clamping mould, which provides a robust clamping force, tailored to meet the specific requirements of the model.

The mould opening and closing stroke can be adjusted according to the size of the product, thereby reducing the time taken to open and close the mould.

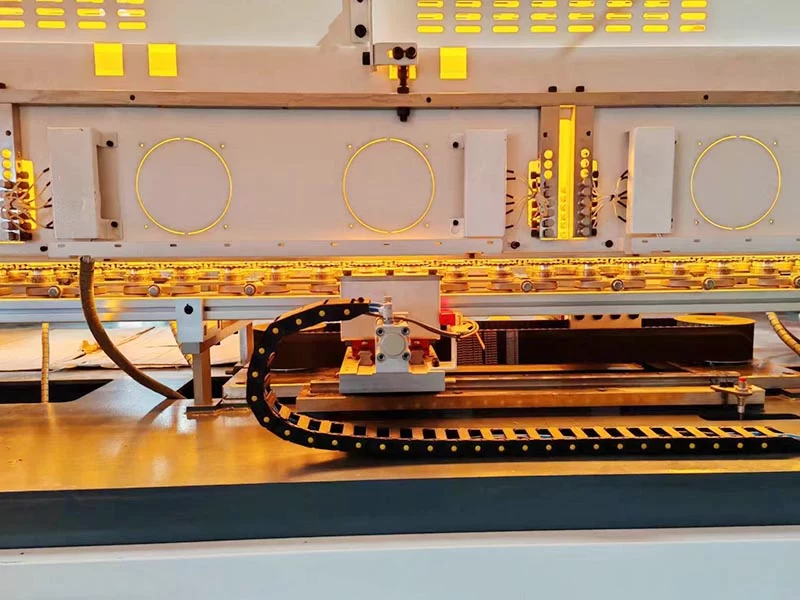

The far-infrared heating tube provides strong penetration and uniform heating of preforms.

Comenster specializes in manufacturing PET bottle blowing machines.Our machine has been exported to the U.S., Canada, Mexico, Australia, Thailand, Brazil, Indonesia, Vietnam, Malaysia, etc. Find more value-added services in Comenster now, the best manufacturer,supplier, and factory in China!

Machine faults:

Clamping jaw failure: adjusting the slide's height or clamping jaw position.

Action jammed: restart the machine can be solved.

Action not in place: check whether there are objects stuck and adjust the gas flow valve.

Preform channel is not uniform: adjusting the position of the preform bin.

Electrical faults:

The machine can not start or stop alarm: check the power supply, wiring or electrical control board, troubleshooting.

Loose electrical connectors in each part: check regularly and make sure the electrical connectors are connected reliably.

Air line malfunction:

Insufficient or excessive pressure: Check air source, air pressure regulator or air line blockage and repair or replace.

System leakage: Replace the air line interface parts or re-encrypt the interface.

Bottle deformation or failure: Adjust the parameters of pressurization, molding and cooling.