- Home

- Solution

- Products

- Services

- Blog

- About

- Contact

Comenster has more than 10 years of technical engineering team in China, focusing on bottled water equipment R & D and manufacturing, we can recommend the right bottled water equipment for you according to different customer situations, one-to-one technical support, from the source water laboratory report to the final product marketing we have a wealth of experience, Comenster has after-sales service agents on all continents, we can help you solve the problem of after-sales service, fast and timely response, no after-sales worries. Comenster has after-sales service agents in every continent, we can help you solve the after-sales service problems nearby, fast and timely response, no after-sales worries.

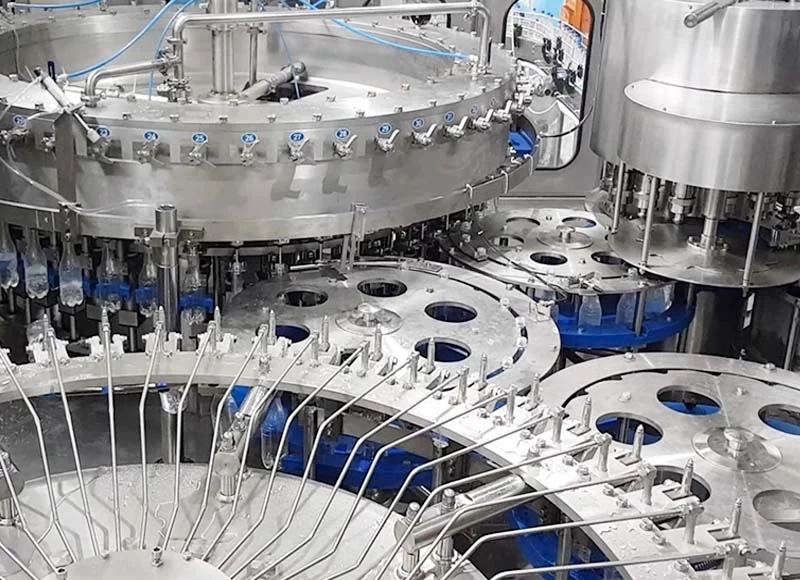

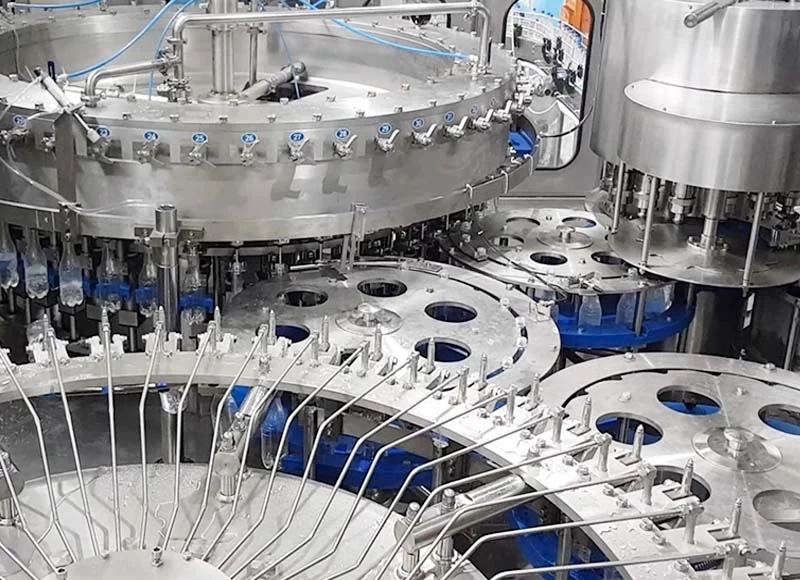

Our blowing-filling-capping combiblock machine represents a significant improvement over traditional blowing machines and filling machines, which are used separately. By integrating the blowing, filling and capping processes into one efficient unit, our machine offers a more streamlined and cost-effective solution. This innovative solution optimizes space utilization and reduces labour costs. The bottle blowing machine blows the bottles and then directly enters the washing and filling process, preventing contamination. With a 10% reduction in energy consumption and a 25% increase in production capacity, it is the preferred choice for large bottled water equipment manufacturers.

Bottle applicable range: 200ml-2.5L

Production capacity: 24000BPH-81000BPH

The water bottling machine has been designed with a three-in-one structure, offering a compact and simple operating system. Its automated operation ensures a high level of efficiency, bottle cleaning before filling, remove contamination after the liquid level filling. The filling level can be automatically adjusted according to the situation, and the bottle cap is attached using a capper or rotary capping, providing high production efficiency.reatment System for pure water bottling line

Application range: PET and glass bottles, aerated and non-aerated beverages, cans, etc.

Bottle volume: 200ml-2.5L

Capacity: 2000BPH-36000BPH

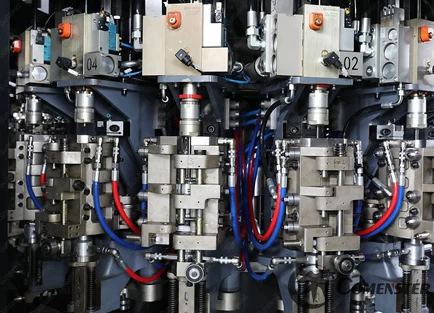

This stretch automatic blow molding machine is designed for automatic feeding from preform to bottle, eliminating the need for human intervention throughout the entire production process. The machine is equipped with different number of cavities, allowing for flexible production capacity.

Production capacity: 2400BPH-24000BPH

Bottle volume: 100ml-2.5L

Large capacity blow molding machine: 3L-20L, applicable with barrel water production line

The marketing of bottled water is primarily focused on the outer packaging and bottle labeling. We offer a range of labeling options to suit different bottle designs. The current standard for bottled water labeling equipment is as follows:

Sleeve labeling machine: suitable for small bottled water equipment production line, as well as beverage production line, the bottle for the whole body sleeve labeling, is conducive to marketing and corporate publicity.

Hot melt OPP labeling machine: suitable for medium and large bottled water production line, high output, bottle labeling effect is neat.

Self-adhesive labeling machine: for the middle and high-end customized water, label design is beautiful, labeling effect is better.

For different packaging specifications and packaging forms, using different packaging equipment, mainly as follows:

Film wrapping machine: PE film is used for packaging, packaging specifications can be customized into 3x4, 2x3, 4x6 and other different specifications.

Carton machine: mainly used for bottle cartoning, specifications can be customized.

Film wrapping machine for finished cartons: the second film wrapping for finished cartons, the appearance of the package is neat and tidy, while avoiding damage to the outside.

Conveying line is the connection part of the whole bottled water equipment, through the conveying line will be filled with bottles from the filling machine transportation to the film packaging machine, the entire transportation process of packaging bottles without reverted rows phenomena, the design of the conveyor line is particularly critical, the conveyor line is designed to be reasonable, will have a direct impact on production line production efficiency, we can be based on the user's site for plant planning and design.

The choice of bottled water equipment is dependent on the packaging materials used. In addition to this, the budget available for the production of bottled water equipment must be considered. The objective is to select the most appropriate bottled water equipment for the task. The following section outlines the various packaging materials and the corresponding bottled water equipment required.

PET plastic bottled water: PET itself with food-grade materials, pollution-free, the use of PET plastic bottles filling, can be packaged water health, pollution-free, while easy to carry, should be bottled water manufacturers suitable for long-distance transportation, lower production costs.

Glass bottle bottled water: glass bottles are generally used in the production of high-end water, the production cost is high, but the profit margin is high, the investment cost is higher than the cost of plastic bottles, but generally glass bottles need to be purchased from the bottle factory, in order to ensure that the bottles are born clean, we are in the production of high-end glass bottled water, using a four-in-one filling machine, glass bottles are sterilized,cleaned, filled and capped.Comenster Bottled water equipment manufacturers have rich experience in glass bottles many types of cap convenience, can be compatible with a variety of glass bottle caps at the same time, such as: aluminum cap, crown cap, easy-open ring cap, etc., one machine multi-purpose, space-saving.

Comenster offers the complete line solutions of water,beverage,milk,beer,edible oil and cosmetic manufacturers and so on: process technology,bottle blowing technology,filling technology and packaging technology and other marketing services.We promise you the most reliable and advanced equipment and solutions in China,and provide you with comprehensive proposals from the beginning .Choose and believe us,we assure you more value added services.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod.

Nemo enim ipsam voluptatem, quia voluptas sit, aspernatur aut odit aut fugit, sed quia consequuntur magni dolores eos, qui ratione voluptatem sequi nesciunt, neque porro quisquam est?

Consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Quis autem vel eum iure reprehenderit, qui in ea voluptate velit esse, quam nihil molestiae consequatur, vel illum, qui dolorem eum fugiat, quo voluptas nulla pariatur?

Nam libero tempore, cum soluta nobis est eligendi optio, cumque nihil impedit, quo minus id, quod maxime placeat, facere possimus.

Nemo enim ipsam voluptatem, quia voluptas sit, aspernatur aut odit aut fugit, sed quia consequuntur magni dolores eos, qui ratione voluptatem sequi nesciunt, neque porro quisquam est?