- Home

- Solution

- Products

- Services

- Blog

- About

- Contact

With the development of the bottled water market and the increasing demand for bottled drinking water in many countries, packaged bottled water has become a major part of people’s daily drinking water. Bottled water is mainly packaged in PET plastic bottles between 500ML-2L, which is easily carried by people for traveling and touring. Bottled water of Blowing Filling Capping Combiblock, and spinning production line is mainly for high speed, large output, high efficiency bottled water production line, the current technology is well established, become a large bottled water production line priority production line equipment.

Specific models are as follows:

Capacity: 12,000 – 56,000BPH

Bottle Size: 500ML -2L

Features:

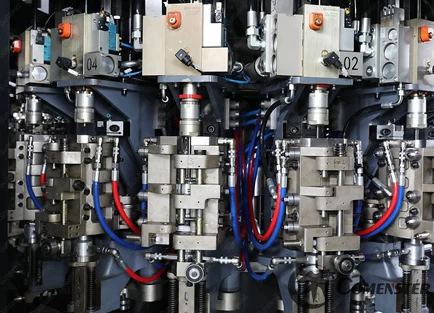

The combination block consists of a blowing unit, a filling unit, and a capping unit. Its motion is synchronously controlled by a servo system, which realizes synchronous and uninterrupted production from bottle blowing to filling and capping. It reduces most of the transportation links, ensures the overall hygiene standard of the whole machine and better helps end users to improve the overall production efficiency.

1. Preform feed-in and unscrambling

Adopting the advanced technology of preform transferring and bottle preform tending, the bottle preforms are weighted on the rotary high speed, the bottle preforms are automatically sorted and conveyed by two inclined rotary cylinders at the same speed, and the remaining bottle preforms are picked by the star wheel and sent back to the bottle preform hopper. The whole bottle sorting process is fully automatic, with high efficiency and no scratches on the bottle blanks.

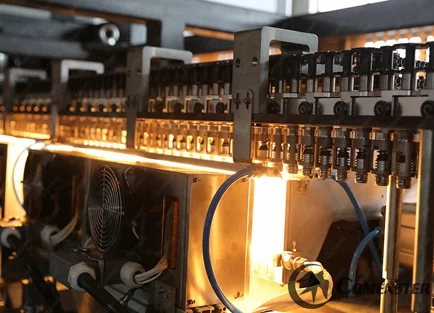

2. Heater

Adopt segmented, rotary heating method, fast heating speed, low energy consumption

3. Blowing unit

After the high precision pick-up of the bottle preform, claw clamps will be heated bottle preform and sent to the mold along a certain cam curve, and after stretching pre-blowing, it will be blown into bottles by connecting high pressure compressed air.

4. Filling unit

The filling machine adopts the gravity filling method. The bottles are rising, the filling valve is opened, and the filling starts. The filling ends when the product rises and blocks the return air hole. After the filling is finished, the bottle mouth moves downward and leaves the filling valve.

5. Capping unit

The bottle enters the capping machine through the transition star wheel. The anti-rotation knife of the capper blocks the bottle neck to keep the bottle vertical and prevent rotation. Under the action of the cam, the whole capping process is completed by the action of cap catching, cap capping, cap rotating and cap exiting. The finished bottles are conveyed to the bottle discharging conveyor through the bottle discharging star wheel and then are sent out of the combi-block.