- Home

- Solution

- Products

- Services

- Blog

- About

- Contact

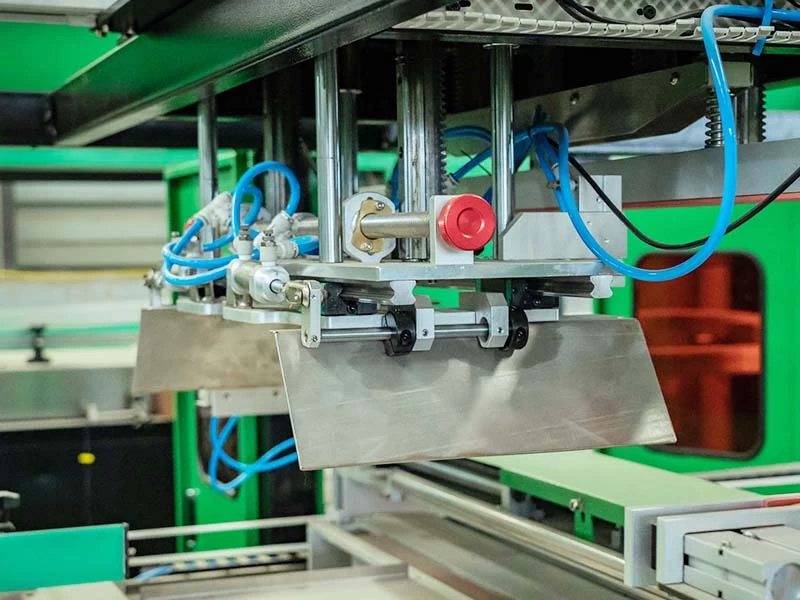

With the continuous development of science and technology and design concepts, the materials, shapes and functions of cosmetic bottles are constantly being innovated, and people are demanding more and more about cosmetic products. This machine can pack plastic containers of different capacities and can be integrated with other bottle making equipment such as blowing and labeling machines to achieve a fully automatic production line for plastic containers.

With the continuous development of science and technology and design concepts, the materials, shapes and functions of cosmetic bottles are constantly being innovated, and people are demanding more and more about cosmetic products. This machine can pack plastic containers of different capacities and can be integrated with other bottle making equipment such as blowing and labeling machines to achieve a fully automatic production line for plastic containers.

Human-machine interface, convenient and quick parameter setting.

Fault self-diagnosis function, fault display simply.

HWF sealing technology, double sealing line sealing uniformity, no breakage, sealing knife is not affected by the temperature of the production environment.

Temperature independent control, better suited to a variety of packaging materials.

Positioning stop function, no sticky knife, no waste of plastic bags.

Simple system, more reliable work, more convenient maintenance.

All controls are realized by software, convenient for function adjustment and technology upgrading, never lagging behind.

Technical parameters:

Host size: 3433LX1300WX2604H(mm)

Conveyor system : 85 mm flexible conveyor system(Recommended)

Weight: Approximately 0.7T

Conveyor system height: 1100土100mm(can be customized)

Bottle height: Height adjustable between 75-290mm; material PET/PE/PP

Production efficiency:Continuous 8-hour production at no less than 95% capacity

Bottle feeding method: Single row bottle feeding

Maximum packaging width: 950mm

Production speed: 7 seconds/row in stable operation, 12 seconds for bag pushing

Power consumption: 2KW, power supply AC3ψ380V

Gas consumption: 6-8kg, 0.5 m³

Finished packaging: