- Home

- Solution

- Products

- Services

- Blog

- About

- Contact

Comenster is a leading manufacturer and supplier of bottle bagging machines, offering a comprehensive range of configurations and models to meet diverse packaging needs. With over a decade of experience in the plastic industry and a stable equipment base, we are well-positioned to provide effective and efficient bottle packaging solutions for beverage, mineral water, dairy, edible oil and other plastic bottles. Our expertise extends to adapting to specific requirements, bag size, production line speed and bottle shapes. The bag opening device lengths and widths of our bagging machine are adjustable to accommodate different bottle types and bag sizes.

Plastic PP /PE/PET empty bottle bagger machine from China,Choose Comenster for your bottle bagging needs!

Packaging material: a roll of thin film

The same roll of film can be used to package different bottle sizes and packaging methods.

Realize automatic bagging, without manual, greatly improve the packaging efficiency.

The double sealing line is uniform and the sealing knife is not affected by the temperature.Without damage, enhances the overall beauty and sealing of the package.

Packaging material: customized bags

According to the different production conditions of the factory,they can customize the plastic bags suitable for different bottle shapes and sizes in advance Need manual bagging, high efficient and easy to operate, the fastest worker can put a bag on just 5 seconds.

Cold temperature knife sealing technology, double sealing line packaging method,tight sealing, will not loosen.

Having Customer Service is very important, but that's just the way it is.

It is important to understand the current status of the industry.

In the production of plastic packaging, especially in the beverage, chemical and other industries, the packaging problem of empty plastic bottles has always been a significant challenge for enterprises. A large number of empty plastic bottles not only take up a lot of storage space, but also increase the cost of manpower and time. To address this challenge, the empty bottle bagging machine was developed as a solution to the bottle accumulation and packaging problem. It is used in conjunction with PE, PP, PET, and other plastic bottle production lines to transform empty bottles into plastic bags, facilitating the recycling of materials. This technology is widely adopted in the food and pharmaceutical industries.

Classification of the plastic empty bottle bagging machine.

The empty bottle bagging machine is divided into two categories: fully automatic and semi-automatic. The automatic bagging machine eliminates the need for manual bagging, with a roll of plastic film provided for automatic bagging and packaging. The semi-automatic model requires the use of a set of plastic bags on the bag opening mechanism. The skilled worker is able to complete the bagging process in just 5 seconds, which is straightforward to operate and use. No training is required.

The advantages of the empty plastic bottle bagging machine.

The empty bottle bagging machine is an efficient and intelligent packaging solution. The machine employs advanced technology and a sophisticated design concept to facilitate the automatic operation of bottle sorting, packaging and stacking. The user simply needs to set the parameters, press the start button and the machine will complete all the necessary work, greatly improving efficiency.

The device is designed for one-click operation, making it simple and convenient to use. The device is designed for ease of use, with simple prompts guiding users through the packaging process. No prior experience or technical expertise is required. Furthermore, the automatic empty bottle bagging machine is equipped with advanced intelligence, enabling it to adjust parameters according to different bottle specifications and packaging requirements, ensuring optimal packaging results.

Furthermore, the empty bottle bagging machine offers numerous advantages, including the ability to save space, reduce transportation costs and enhance safety. The automatic packaging process allows for the neat stacking of a large number of empty bottles, reducing the need for storage space. Furthermore, the packaged bottle is more compact, facilitating transportation and reducing transportation costs. Furthermore, the automatic empty bottle bagging machine can also reduce manual operation, reduce operational risk, and improve work safety.

Potential applications include:

Water and beverage industry: mineral water, pure water, juice drink,etc.

Edible oil industry: large barrel special bottle, other packaging specifications;

Cosmetics bottles: customized diversified bottle package specifications.

Pharmaceutical industry: PET material of alcohol bottles and disinfectant bottles.

In summary, the empty bottle bagging machine is an effective, intelligent and convenient packaging solution, with its one-click operation making it simple to address bottle accumulation issues. Both large enterprises and small and medium-sized enterprises can introduce empty bottle bagging machine to optimize their production processes, improve their production efficiencies, reduce their production costs and inject new impetus into their development. As technology advances and the product gains further traction in new markets, the empty bottle baler will become an increasingly valuable tool for businesses of all sizes.

The empty plastic bottle bagging machine is a specialized piece of equipment used in PE, PP, PET and other plastic bottle production lines. Its purpose is to automatically put empty bottles into plastic bags, thus facilitating the cleaning and turnover of bottles. This equipment is widely used in the food and pharmaceutical industries. The following article will provide some guidance on how to select the most suitable bagging machine.

To select the most suitable baler from Comenster Machinery, simply provide the following information:

1. Bottle Type

A. There are several bottle types that a bagging machine can be compatible with. However, the changed parts need to be replaced, including the push plate and bag support mechanism.

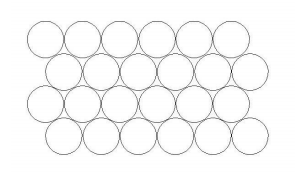

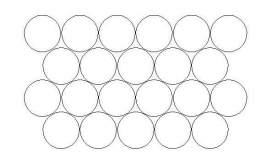

B. Bottle shape: square bottles, round bottles, other shape bottles, etc. It is not necessary to arrange square bottles. Round bottles should be arranged as far as possible and packed as compactly as possible. Please confirm with the technical department whether oval bottles, slender bottles, cone bottles, etc. are suitable.

C. Bottle capacity: Different bottle volume is suitable for different models.

2.Packaging specifications

Please provide the seller with the packaging specifications you require. This should include details of the number of rows of each bag, the number of square bottles or large bottles, the number of odd and even rows of round bottles, and any dislocation.

3.Production capacity of bottle blow molding machine

The production capacity of bottle blow molding machine is an important basis for equipment selection. Please inform the seller of the actual production capacity of your bottle blow molding machine, as this will help them select the appropriate bagging machine. The production speed of the bagging machine should be larger than the production speed of the bottle blow molding machine, in order to achieve the perfect packaging effect.

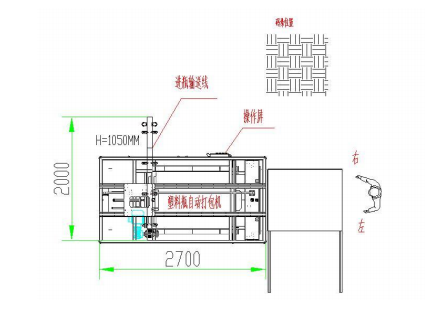

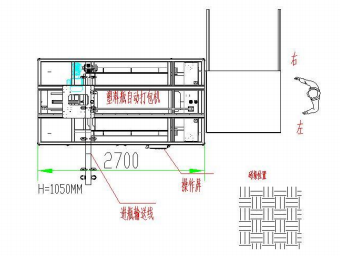

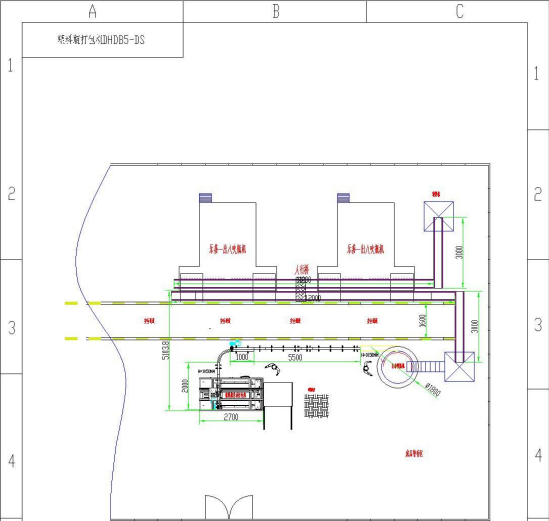

4.Direction of operation and bottle infeed

Due to the changing location of the customer, the bagging machine is set up in the customer's production workshop, and the bottle entering the machine may be left or right; similarly, the operation screen of the machine must also be located according to the location situation, and the two directions should be confirmed before the equipment is made. If space permits, we recommend that the direction of operation is the same as that of the cylinder. When the bagging machine is working, it is more convenient for the operator to operate the equipment.

5. Bagging platform height

The height of the workbench refers to the distance between the arrangement platform and the ground inside the machine. The height of the bottle delivery line, the height of the discharge platform and the bagging height of the workers should be consistent with this height. After years of design experience in our company, 1050mm is the most convenient gold size for operator bags. This height can be customized if required to be consistent with the front end equipment, but the minimum recommendation is not less than 800mm.

6. Bag Material

There are three types of common bag materials in the market: PE plastic bags, PVC plastic bags, woven bags, PE and PVC plastic bags can be used with hot sealing function, automatic sealing function, woven bag packaging without automatic sealing function. Most customers are using plastic bag packaging, cold and hot sealing knife automatic sealing, sealing close without broken bag.

Finally, you need to determine your own budget. Different bagging machine models have their own characteristics and advantages in different application scenarios and budgets. If the budget is sufficient and the pursuit of automation workshop, you can choose the automatic machine!

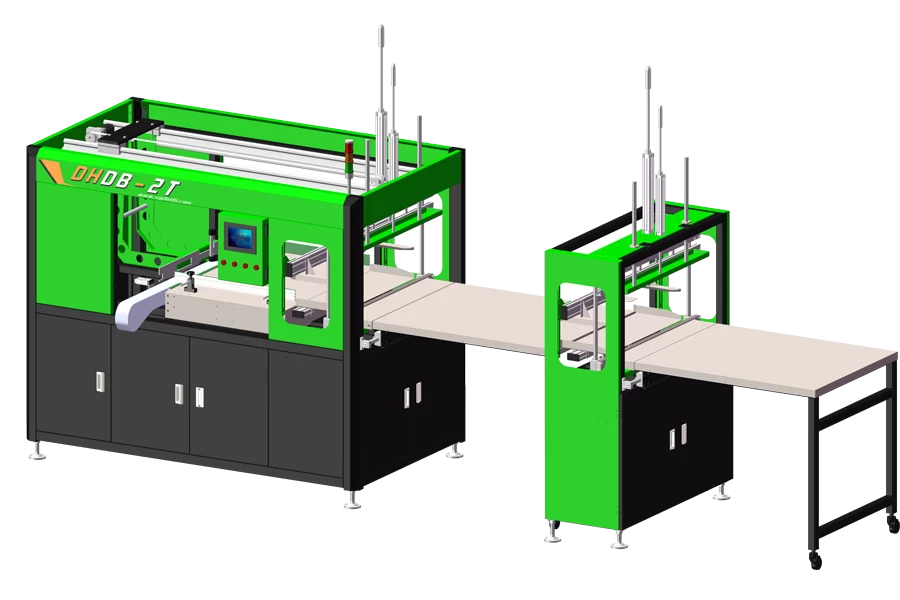

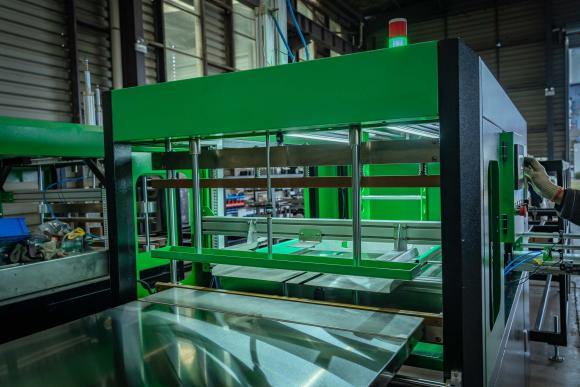

The example layout of bagging machine in your factory.

As society and science and technology continue to advance, the manual bottle package method is being replaced by the automatic equipment. The rapid development of technology is a clear indicator of social progress. By having more time to seize the market and improve efficiency, factories can gain a competitive advantage. This makes a good equipment an indispensable weapon for a company.

For bottle blowing manufacturers, the empty bottle bagging machine is a device used to automatically pack the empty bottles. This kind of equipment usually has the functions of automatic bottle delivery, automatic bagging, automatic sealing, automatic packaging and so on, which can greatly improve the packaging efficiency, reduce the manual operation and reduce the production costs.

Automatic bottle bagging machine can bring several benefits to the enterprise.

High efficiency. The automatic bagging machine can continuously and quickly complete the packaging task, greatly improving production efficiency. In comparison to manual packaging, the machine operates more rapidly and precisely, thereby reducing delays and errors that may be caused by human factors.

Cost savings: Automatic bagging machine can help to reduce labour costs and reliance on a large number of workers. Furthermore, the machine's accuracy and stability result in reduced material waste and defective rates, thereby reducing production costs.

Quality stability: the automatic bagging machine employs a precise control system and mechanical components to guarantee the quality of each package is stable and consistent. This helps to enhance the overall quality of the products and meet the higher requirements of customers.

Improve the working environment: the automatic bagging machine can replace manual packaging in harsh or dangerous working environments, thus improving working conditions and reducing the risk of industrial injury.

The automatic bagging machine can reduce labour intensity by undertaking heavy packaging tasks, thus freeing up workers from intensive manual labour and reducing labour intensity.

In conclusion, the automatic empty bottle bagging machine offers a number of advantages, including high production efficiency, stable packaging quality, simple operation, convenient maintenance, environmental protection and energy saving, and a wide application range. These advantages make the automatic bagging machine an invaluable tool for businesses seeking to boost production efficiency, reduce operational costs and enhance product quality.

As people's living standards have improved, dairy products have become an increasingly common part of daily family life. In particular, bottled milk is easy to carry when people are shopping. In the production of bottled milk, the bottles are purchased in bulk. The milk bottles are then packed into a bag through an automatic bagging machine and transported to the milk manufacturer for filling. The milk bottle bagging machine has become the most popular packaging equipment in the bottle blowing factory.

The milk bottle bagging machine is divided into two parts according to the automation of the packing equipment:

The semi-automatic milk bottle bagging machine costs between $10,000 and $20,000.

The full automatic milk bottle bagging machine costs between $50,000 and $80,000.

The final equipment price is determined by the configuration and process of the milk bottle bagging machine. It is recommended to consult the bagging machine manufacturer to obtain a quote according to your requirements.