In the production of plastic packaging, especially in the beverage, chemical and other industries, the packaging problem of empty plastic bottles has always been a significant challenge for enterprises. A large number of empty plastic bottles not only take up a lot of storage space, but also increase the cost of manpower and time. To address this challenge, the empty bottle bagging machine was developed as a solution to the bottle accumulation and packaging problem. It is used in conjunction with PE, PP, PET, and other plastic bottle production lines to transform empty bottles into plastic bags, facilitating the recycling of materials. This technology is widely adopted in the food and pharmaceutical industries.

Classification of the plastic empty bottle bagging machine.

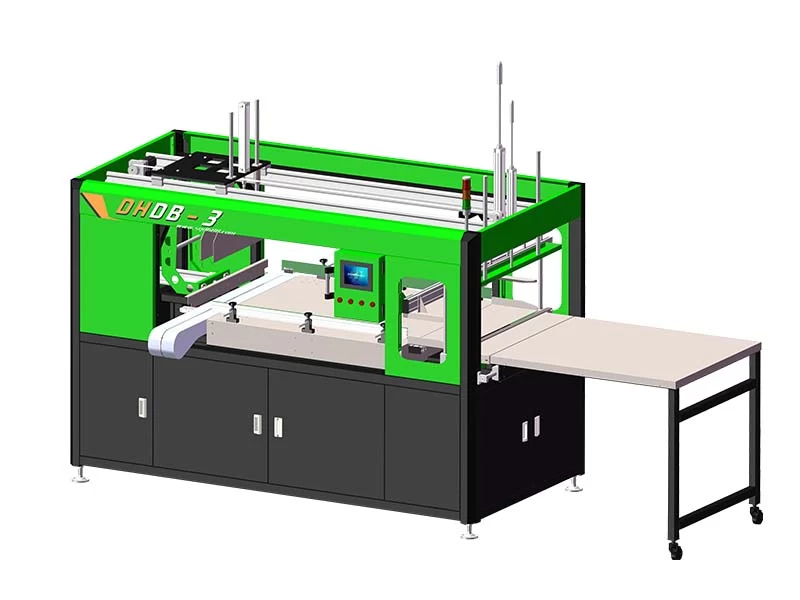

The empty bottle bagging machine is divided into two categories: fully automatic and semi-automatic. The automatic bagging machine eliminates the need for manual bagging, with a roll of plastic film provided for automatic bagging and packaging. The semi-automatic model requires the use of a set of plastic bags on the bag opening mechanism. The skilled worker is able to complete the bagging process in just 5 seconds, which is straightforward to operate and use. No training is required.

The advantages of the empty plastic bottle bagging machine.

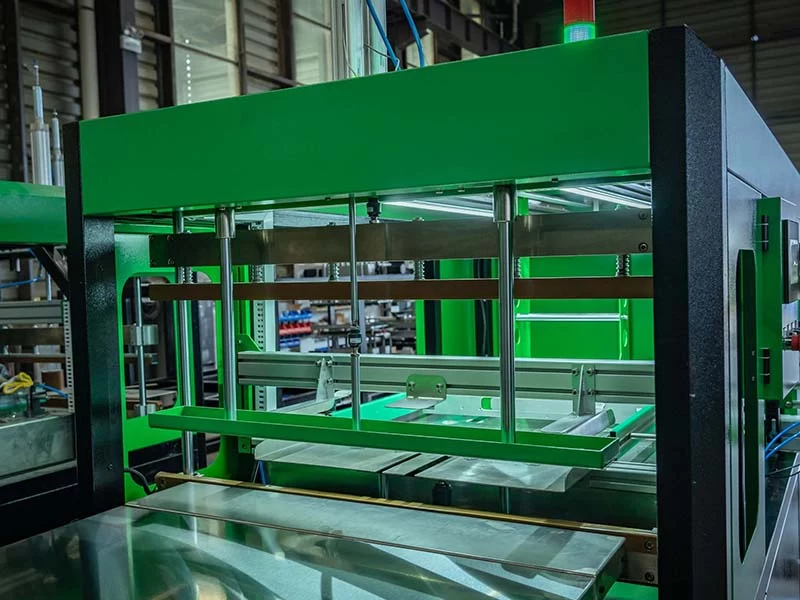

The empty bottle bagging machine is an efficient and intelligent packaging solution. The machine employs advanced technology and a sophisticated design concept to facilitate the automatic operation of bottle sorting, packaging and stacking. The user simply needs to set the parameters, press the start button and the machine will complete all the necessary work, greatly improving efficiency.

The device is designed for one-click operation, making it simple and convenient to use. The device is designed for ease of use, with simple prompts guiding users through the packaging process. No prior experience or technical expertise is required. Furthermore, the automatic empty bottle bagging machine is equipped with advanced intelligence, enabling it to adjust parameters according to different bottle specifications and packaging requirements, ensuring optimal packaging results.

Furthermore, the empty bottle bagging machine offers numerous advantages, including the ability to save space, reduce transportation costs and enhance safety. The automatic packaging process allows for the neat stacking of a large number of empty bottles, reducing the need for storage space. Furthermore, the packaged bottle is more compact, facilitating transportation and reducing transportation costs. Furthermore, the automatic empty bottle bagging machine can also reduce manual operation, reduce operational risk, and improve work safety.

Potential applications include:

Water and beverage industry: mineral water, pure water, juice drink,etc.

Edible oil industry: large barrel special bottle, other packaging specifications;

Cosmetics bottles: customized diversified bottle package specifications.

Pharmaceutical industry: PET material of alcohol bottles and disinfectant bottles.

In summary, the empty bottle bagging machine is an effective, intelligent and convenient packaging solution, with its one-click operation making it simple to address bottle accumulation issues. Both large enterprises and small and medium-sized enterprises can introduce empty bottle bagging machine to optimize their production processes, improve their production efficiencies, reduce their production costs and inject new impetus into their development. As technology advances and the product gains further traction in new markets, the empty bottle baler will become an increasingly valuable tool for businesses of all sizes.

Related articles